Induskart: Engineering Excellence in Flange Manufacturing in India

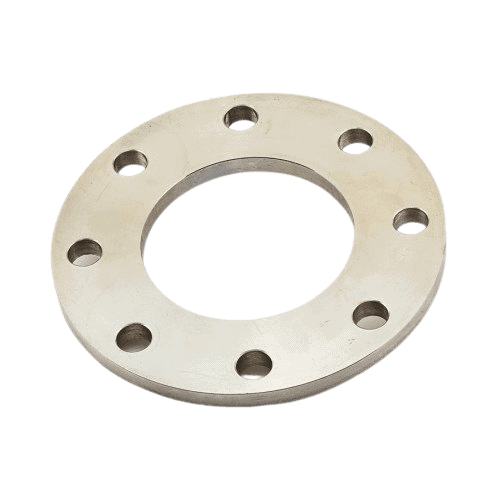

Induskart is a leading flange manufacturer in India, specializing in the production of steel flanges including carbon steel flanges, alloy steel flanges, and stainless steel flanges. Based out of Vadodara, we are known for our engineering excellence and high-quality flange products. As a trusted supplier and exporter in India, Induskart manufactures a wide range of pipe fittings and flanges such as weld neck flange, threaded flange, weld neck flange, and socket weld flange. Our flanges are manufactured in materials like duplex, super duplex, and stainless steel to meet various industry requirements. Induskart also produces lap joint flange, blind flange, and plate flange with sizes ranging from ½”nb to 48”nb. The company is ISO certified and is known for our engineering expertise.

Introduction

Induskart is a leading stainless steel flanges manufacturer and supplier in India, providing a wide range of flanges including carbon steel, super duplex, and ms flanges. The company, known for its high-quality products and timely delivery, manufactures stainless steel flanges according to flanges specification from ½”nb to 48”nb. With a customer base in India, Induskart has established itself as one of the top flange suppliers.

Flanges play a crucial role in industrial applications and systems, connecting pipes and valves securely to prevent leakage. Whether it’s a slip-on flange, orifice flange, or reducing flange, each type of flange is used for specific purposes in different industries. As a steel flanges manufacturer in India, Induskart understands the importance of providing high-quality products that meet the requirements of various industries.

Our Clients

Introduction

Induskart is a leading stainless steel flanges manufacturer and supplier in India, providing a wide range of flanges including carbon steel, super duplex, and ms flanges. The company, known for its high-quality products and timely delivery, manufactures stainless steel flanges according to flanges specification from ½”nb to 48”nb. With a customer base in India, Induskart has established itself as one of the top flange suppliers.

Flanges play a crucial role in industrial applications and systems, connecting pipes and valves securely to prevent leakage. Whether it’s a slip-on flange, orifice flange, or reducing flange, each type of flange is used for specific purposes in different industries. As a steel flanges manufacturer in India, Induskart understands the importance of providing high-quality products that meet the requirements of various industries.

Overview of Flanges

Flanges are widely used in industrial piping systems to connect pipes, valves, pumps, and other equipment. They provide a solid and secure connection, ensuring that the system operates smoothly and efficiently. Carbon steel flange manufacturers like Induskart are one of the leading suppliers of quality stainless steel and flanges in India. We offer a wide range of flanges from ½”nb to 48”nb, including duplex flanges, super duplex flanges, large diameter flanges, and ANSI flanges. Some of the popular types flanges manufactured by us include slip on flange, threaded pipe, and ASME flanges. Whether you need flanges exporter or flanges manufacturers in India, we have you covered with our wide range of products.

Our Clients

Induskart: Your Leading Flange Manufacturer with Expertise in High-quality Steel Flanges

Induskart is a leading flange manufacturer with extensive expertise in the production of high-quality steel flanges for various industries. Our manufacturing capabilities allow us to produce flanges from ½”nb to 48”nb to meet the diverse needs of our clients. As a reputable forged flanges manufacturer, we specialize in the production of popular types of flanges that are in high demand in the market. Our skilled team is well-versed in the art of forging flanges to ensure superior strength and durability in our products. With a commitment to precision and quality, Induskart is the trusted choice for all your flange manufacturing needs.

Overview of manufacturing facilities and technologies employed by Induskart

Induskart utilizes state-of-the-art manufacturing facilities to produce a wide range of industrial products. Our facility is equipped with advanced technologies and machineries to ensure high-quality production of various components. One of the key products we specialize in is flanges from ½”nb to 48”nb, which are essential components in piping systems. These flanges manufactured by us are known for their precision and durability, making them ideal for use in diverse industrial applications.

Additionally, we also specialize in producing lapped pipe joints, which are used for connecting pipes securely. Our manufacturing processes for lapped pipes involve stringent quality control measures to ensure that they meet industry standards. With our commitment to excellence, Induskart continues to be a trusted provider of high-quality industrial products for our customers.

Material selection for flange manufacturing (carbon steel flanges, stainless steel, alloy steel, etc.)

Induskart has state-of-the-art manufacturing facilities equipped with advanced technologies to produce a wide range of industrial products. We specialize in manufacturing flanges from ½”nb to 48”nb to cater to the diverse needs of our customers. The flanges manufactured by us are known for their high quality and precision engineering, making them suitable for various applications in industries such as oil and gas, petrochemicals, and construction. Our production process also includes the use of lapped pipe technology, which ensures seamless and leak-proof connections for our customers’ piping systems. With a focus on innovation and excellence, Induskart continues to be a trusted provider of industrial products in the market.

Material standards and grades (ASTM, ANSI, DIN, etc.)

Material standards and grades such as ASTM, ANSI, and DIN play a crucial role in ensuring the quality and reliability of industrial equipment and components. Flanges ranging from ½”nb to 48”nb must meet specific standards to ensure proper function and compatibility with other parts. These standards define the requirements for materials, dimensions, testing, and performance characteristics of flanges, helping manufacturers produce consistent and reliable products. For example, the ASTM standard specifies the chemical composition and mechanical properties of materials used in flange manufacturing, while the ANSI standard establishes dimensional tolerances and pressure ratings. Similarly, the DIN standard sets guidelines for quality control and traceability in flange production. By adhering to these standards, manufacturers can ensure that their products meet the necessary requirements for safety and performance in a wide range of industrial applications.

Impact of material choice on flange performance and applications

– Advanced manufacturing processes and quality control measures

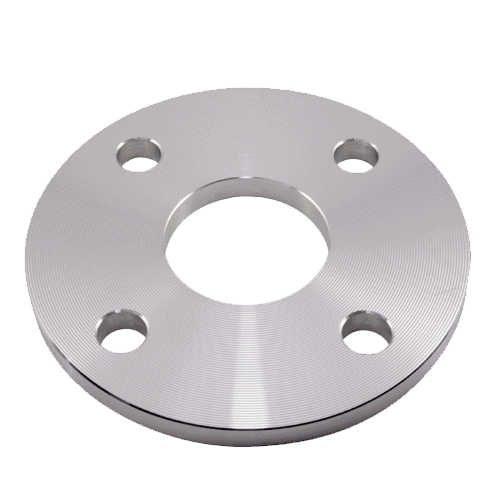

Flanges from ½”nb to 48”nb play a crucial role in various industries, ensuring leak-proof connections in piping systems. The choice of material for flanges significantly impacts their performance and applications. Different materials offer varying levels of corrosion resistance, strength, and durability, leading to diverse benefits in specific environments. For instance, stainless steel flanges are ideal for applications requiring high resistance to corrosion, while carbon steel flanges are preferred for their strength and cost-effectiveness. Advanced manufacturing processes and quality control measures further enhance the performance of flanges. Precision machining and testing help ensure the dimensional accuracy and integrity of flanges, minimizing the risk of leaks or failures. By selecting the appropriate material and implementing stringent quality control measures, industries can optimize the performance and reliability of their flange connections.

CNC machining, forging, and casting techniques

CNC machining is a precise manufacturing process that involves using computer-controlled machines to remove material from a workpiece. This technique is ideal for creating complex shapes and intricate designs with high accuracy and repeatability. CNC machining allows for a wide range of materials to be processed, including metals, plastics, and composites. Flanges from ½”nb to 48”nb can be easily produced using CNC machining, ensuring a tight fit and optimal performance.

On the other hand, forging is a traditional metalworking method that involves shaping metal using compressive forces. This technique is known for producing parts with superior strength and durability. Forging is commonly used in the automotive, aerospace, and energy industries to create components such as gears, crankshafts, and connecting rods.

Casting is another popular manufacturing process that involves pouring molten metal into a mold cavity and allowing it to solidify. This technique is ideal for producing complex shapes and large quantities of parts at a low cost. Flanges from ½”nb to 48”nb can be easily cast using a variety of metals, including iron, steel, and aluminum.

Non-destructive testing (NDT) and dimensional inspections for quality assurance

CNC machining utilizes computer numerical control to create precision parts by removing material from a solid block. This method is often used for producing complex shapes and high volumes of parts. On the other hand, forging involves shaping metal through compressive forces, resulting in strong and durable components. Lastly, casting techniques involve pouring molten metal into a mold to create intricate shapes, including flanges from ½”nb to 48”nb.

Flange Design and Specifications

Flange design and specifications are critical components in the field of piping engineering, ensuring the integrity and reliability of piping systems across a wide range of industries, including oil and gas, chemical processing, and power generation. This section delves into the specifics of flange design standards, pressure-temperature ratings, facing types, and custom flanges, offering a comprehensive overview tailored for professionals seeking detailed and technical insights.

Flange Design Standards

Key to the standardization of flanges are the ASME B16.5 and ASME B16.47 standards, established by the American Society of Mechanical Engineers (ASME). These standards delineate dimensions, tolerances, marking, and material requirements for flanges, ensuring compatibility and interchangeability.

- ASME B16.5 applies to pipe flanges and flanged fittings made from cast or forged materials, as well as plate flanges and blind flanges in nominal sizes ranging from 1/2 inch to 24 inches. It encompasses pressure ratings from Class 150 to Class 2500, catering to a wide spectrum of pressure requirements.

- ASME B16.47 expands on the scope of B16.5, covering large diameter steel flanges from 26 inches up to 60 inches. It is divided into Series A (MSS SP-44) and Series B (API 605) for different dimensional specifications, thereby accommodating various design and service conditions.

Fitting Selection and Integration

Pressure-Temperature Ratings

The pressure-temperature rating of a flange defines its maximum allowable working pressure at a specified temperature. These ratings are crucial for selecting appropriate flanges that can withstand the operational demands without compromising safety or efficiency. ASME standards specify these ratings, ensuring that flanges can be selected based on precise engineering requirements, considering the fluid’s nature, operating conditions, and material properties of the flange.

Facing Types and Their Applications

The flange face is the surface that hosts the sealing mechanism. The choice of facing type is pivotal, as it influences the seal’s quality, the ease of installation, and maintenance requirements. Common facing types include:

- Raised Face (RF): The most commonly used type, featuring a raised area that concentrates the bolt load, suitable for a wide range of applications in moderate to high-pressure systems.

- Flat Face (FF): Characterized by a flat surface extending to the full diameter of the flange. FF is typically used with cast iron flanges and in applications where the sealing pressure is low.

- Ring Type Joint (RTJ): Designed for high-pressure/temperature applications, RTJ flanges have a grooved surface that accommodates a metal ring gasket. This design ensures a robust seal under extreme conditions.

- Tongue and Groove (T&G) and Male & Female (M&F): These types involve matching pairs of flanges where one flange features a protrusion (tongue) that fits into a groove on the mating flange, offering a tight seal suitable for moderate pressure applications without excessive bolt tightening.

Pipe Flange Solutions

Custom Flanges and Engineering Solutions

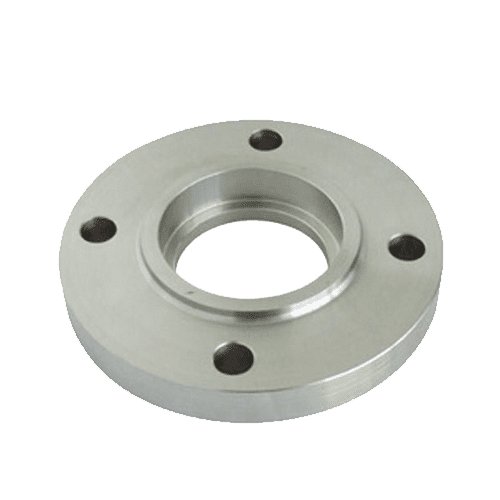

In scenarios where standard flanges cannot meet specific project requirements, custom flanges provide a solution tailored to unique operational needs. This customization can address unusual dimensions, special material requirements for corrosive or extreme temperature environments, or unique pressure ratings beyond the scope of standard classifications.

Supplier Collaboration

Custom flange design involves close collaboration between engineers and manufacturers to ensure that the final product adheres to all relevant standards while meeting the application’s unique demands. Advanced manufacturing techniques, such as precision machining, have expanded the possibilities for custom flange solutions, enabling more complex designs and rapid prototyping for testing and validation.

Types of flanges (Weld Neck, Slip-On, Blind, Threaded, Lap Joint, Socket Weld, etc.)

Flanges are essential components in a pipe system, providing a means for connecting pipes, valves, pumps, and other equipment. At our leading manufacturer of stainless steel pipe flange division, we offer a wide range of flanges in a variety of types and sizes, ranging from ½”nb to 48”nb. As a flanges manufacturer and supplier of stainless steel flanges, we specialize in steel flanges and carbon steel flanges, including weld-neck flange, socket-weld pipe, threaded pipe flanges, and more. Our quality flanges are designed for durability and performance, with options for ss flanges, super duplex steel, and custom flanges manufacturers. Whether you need a blind flange and blind, lap joint flange, or split flange, our approved flanges are sure to meet your requirements.

Weld Neck Flange: Features a long tapered hub that provides strong reinforcement for use in high-pressure applications. It is welded to the pipe, ensuring a durable and leak-proof connection. Ideal for critical processes where the conditions involve high pressure, sub-zero or elevated temperatures.

Slip-On Flange:Easily slides over the end of a pipe and is then welded in place. It is preferred for its ease of alignment and installation. Suitable for low-pressure and temperature applications, offering a cost-effective solution for flanged joints.

Blind Flange:A solid disc used to blank off the end of a piping system or pressure vessel opening. It provides access for inspection, cleaning, or modification of a sealed system. Utilized in high-pressure and high-temperature environments where safety and reliability are paramount.

Threaded Flange:Designed with threads on the inner diameter that connect with matching threads on a pipe. This type allows for assembly without welding, making it suitable for explosive or highly flammable conditions where welding is hazardous.

Lap Joint Flange:Consists of two components: a stub end and a loose backing flange. The stub end is welded to the pipe, and the flange is free to rotate around the stub end. Ideal for systems requiring frequent dismantling for inspection and cleaning.

Socket Weld Flange:Designed for small diameter high-pressure applications. The pipe is inserted into the flange socket, and the connection is made with a single fillet weld at the flange’s hub. This ensures a smooth bore and better fluid flow.

Orifice Flange:Used in conjunction with orifice meters for the purpose of measuring the flow rate of liquids or gases in the pipeline. These flanges are typically supplied with pairs with a corresponding orifice plate and are equipped with jack screws to facilitate the removal of the orifice plate.

Spectacle Blind Flange: A combination of a spacer and a blind flange, used to isolate a section of pipe for maintenance or shutdowns. It can be rotated to block or allow the flow through the pipe.

Long Weld Neck Flange: Similar to a standard weld neck but with an extended neck, often used in high-pressure, high-temperature, or high-impact applications where the strength of the weld neck is necessary but the flange needs to be extended.

Criteria for selecting the right flange (pressure ratings, temperature range, connection types, etc.)

When selecting the right type of flange for a project, there are several key criteria to consider. One important factor is the pressure ratings of the flange, which must be suitable for the system in which it will be used. Another important consideration is the temperature range that the flange will be exposed to, as different materials have different temperature limitations. Additionally, the connection types of the flange must match those of the pipes it will be joining, such as lapped or forged rings. At our company in Gujarat, we offer a wide range of flanges from ½”nb to 48”nb, all manufactured by us to ensure quality and reliability. Our flanges are usually available at the best price on the market, making us a top choice for all your flange needs.

Applications of Induskart Flanges

Induskart flanges have been successfully implemented across a broad spectrum of industries, demonstrating their capacity to address complex engineering challenges with efficiency and reliability.

Case Studies Highlighting Successful Applications

- Oil & Gas: In the demanding environment of oil and gas extraction and processing, Induskart flanges have been pivotal in ensuring leak-proof and robust connections under high pressure and temperature conditions, enhancing operational safety and efficiency.

- Chemical Processing: The chemical industry, with its corrosive substances and stringent safety standards, has benefited from the use of Induskart flanges made from materials resistant to chemical attack, ensuring the integrity of piping systems over extended periods.

- Water Treatment: In water treatment facilities, where the prevention of contamination is paramount, Induskart flanges have ensured reliable separations between different process streams, contributing to the safe treatment and distribution of water.

Versatility in Addressing Complex Engineering Challenges

Induskart flanges demonstrate remarkable versatility, accommodating various sealing faces (RF, FF, RTJ, etc.) and materials that cater to specific industry requirements. This adaptability allows engineers to overcome complex challenges, such as extreme temperatures, pressures, and corrosive environments, ensuring the longevity and reliability of piping systems.

Navigating the Challenges of Flange Manufacturing

The manufacturing of flanges faces several challenges, from ensuring dimensional accuracy and material integrity to meeting the diverse specifications of different industries

Common Challenges and Induskart’s Solutions

- Material Quality: Induskart addresses material quality challenges by sourcing raw materials from reputable suppliers, ensuring that all flanges meet the highest standards for durability and performance.

- Precision Engineering: With state-of-the-art manufacturing facilities, Induskart achieves high precision in flange dimensions and tolerances, essential for ensuring leak-proof connections.

Innovation and Continuous Improvement

Induskart is committed to innovation and continuous improvement, incorporating advanced manufacturing technologies and rigorous quality control measures. This approach not only enhances flange quality and performance but also addresses custom requirements efficiently, enabling the development of solutions for even the most demanding applications.

The Future of Flange Manufacturing with Induskart

As the industry evolves, Induskart is at the forefront of adopting emerging trends and technologies to stay ahead in flange manufacturing.

Adapting to Emerging Trends

- 3D Printing of Flanges: Induskart explores the potential of 3D printing to produce flanges, offering unprecedented flexibility in design and rapid prototyping capabilities, paving the way for innovative solutions tailored to specific customer needs.

- Use of Exotic Materials: Recognizing the need for flanges that can withstand extreme conditions, Induskart invests in the use of exotic materials, such as superalloys, to enhance the performance and longevity of flanges in harsh environments.

Commitment to Sustainability

Sustainability is a cornerstone of Induskart’s manufacturing processes. The company is dedicated to minimizing its environmental impact, employing eco-friendly practices, such as waste reduction, recycling, and the use of renewable energy sources. This commitment ensures that Induskart’s flanges are not only high in quality and performance but also manufactured with a reduced environmental footprint.

Through these initiatives, Induskart continues to shape the future of flange manufacturing, driven by a commitment to quality, innovation, and sustainability, meeting the evolving needs of industries worldwide.

Conclusion

Throughout this exploration of Induskart’s contributions to the flange manufacturing industry, it’s clear that the company stands as a pivotal player in advancing the field within India. Through its commitment to quality, innovation, and sustainability, Induskart has demonstrated unparalleled versatility and expertise in addressing the complex challenges faced by a variety of industries, from Oil & Gas to Water Treatment.

Induskart’s Strengths and Industry Advancement

Induskart’s strengths lie in its rigorous adherence to international standards, the application of cutting-edge manufacturing technologies, and a steadfast dedication to sustainability. The company has successfully navigated the challenges inherent in flange manufacturing, delivering products that meet the highest standards of precision, durability, and performance. By continuously embracing emerging trends, such as 3D printing and the use of exotic materials, Induskart is not only meeting the current demands of the industry but is also paving the way for future advancements.

Final Thoughts

When it comes to securing piping systems in a reliable and leak-proof manner, the Flanges from Induskart stand unmatched. Engineered with precision in Vadodara, Gujarat, our flanges meet rigorous international standards, ensuring compatibility and durability across a multitude of industrial applications. For projects where quality cannot be compromised, turn to Induskart for flanges that deliver under pressure.

Need to discuss your flange requirements or obtain a quote? Reach out to us today at

Email: info@induskart.co.in

Mobile: 9726429403, 9978796000, 9726419401, 9726419402

Client Testimonials

Induskart's pipe fittings manufacturing in India delivers top-tier products, known for their reliability and precision, making them a trusted choice in the piping sector.

Brij Bhushan Bhardwaj

Induskart is where dreams are nurtured and turned into reality. The good mentor support and a cooperative team create an ideal atmosphere for personal growth. The supportive management encourages you to explore your potential and excel. I'm grateful to have built my career with Induskart and achieved my goals.

Kaivalya Nilkanth

Building my career with Induskart has been an incredible journey. The professional environment here fosters growth and learning. The mentor support is exceptional, and the management is genuinely supportive. The social culture adds a friendly touch, making every day enjoyable. Thanks to Induskart, I've achieved my career objectives.

Ruchi Khanvilkar

Dispatch Gallery

Blind Flange Manufacturers

Blind Flange: A blind flange is a solid flange as shown below. The purpose of these is to block off a section of pipe or a nozzle on a vessel that is not used. (A nozzle is typically...

CS Flanges

Get high-quality Carbon Steel Flanges at the best prices. Flanges are basic mechanical devices used to connect pipes, valves, pumps, and more. They are circular and usually welded or threaded with each other.

They come in two...

Custom Flange

Flat Face Flange

Flat Face Flange: A flat faced flange, abbreviated as FF, is a flange that is machined flat and does not have a ridge like a raised face or ring type joint flange. The flat surface allows for the...

Lap Joint Flange

MS Flange Manufacturer in India: Induskart’s Pinnacle of Steel Mastery

RTJ Face

RTJ Face: RTJ flanges seal when tightened bolts compress the gasket between the flanges into the grooves, deforming (or “Coining”) the gasket to make Intimate Contact inside the grooves, creating a metal to metal seal. An RTJ flange...

Slip On Flange

Slip On Flange: Slip on Flange is essentially a ring that is placed over the pipe end, with the flange face extending from the end of the pipe by enough distance to apply a weld bead on the...

Socket Welding Flange

Socket Weld Flange: A Socket Weld is a pipe attachment detail in which a pipe is inserted into a recessed area of a Valve, fitting or flange. In contrast to butt weld fittings, Socket Weld fittings are mainly...

Ss Flanges Manufacturer In India

STAINLESS STEEL SS FLANGES

Induskart is the leading supplier of SS flanges. Flanges are basic mechanical devices used to connect pipes, valves, pumps, and more. They are circular and usually welded or threaded with each other.

They come...

Threaded (Screwed)

Threaded Flange (Screwed): Threaded Pipe Flanges. Threaded pipe flanges are similar to slip-on pipe flanges except the bore of threaded pipe flange has tapered threads. Threaded pipe flanges are used with pipes that have external threads. Threaded pipe flanges are often...