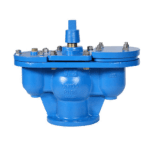

High-Efficiency Air Release Valve for Industrial Applications

The hydraulic system of any equipment can be destroyed by air, but systems are made safer and more reliable with the help of Air Release Valves. These valves are designed to let go of trapped gases or air in the system when it is still under pressure. They find their best application in places such as water treatment plants, and irrigation systems among others that need to deal with large volumes of water.

Material Specifications:

To ensure that it will last long and will not easily corrode, the Air Release Valve is made of strong stainless steel with polymer seals that are also tough. It provides resistance against corrosion and durability in various industrial settings due to the materials used.

Technical Specifications:

This valve has a flanged end connection for secure installation and can handle pressures up to 150 psi. Because of its small size design, it can be installed in tight spaces which enhances its functionality as an air control valve for different purposes. The temperature range where this valve operates is from -10°C to 110°C thus it can be used in many industries.

Standards and Compliance

The standards followed by the manufacturer while designing this product include ISO 9001 (Quality Management Systems) and ISO 14001 (Environmental Management). For worldwide safety measures, ASME compliance ensures that it meets all necessary conditions required for quality assurance.

Usage Instructions

For the best performance of the Air Release Valve, it is recommended that you clean the vent port periodically. Installation should be done by a professional to avoid problems like wrong positioning or insufficient sealing. If the valve fails to release air as it ought to, check for blockages and mechanical wear during troubleshooting. Efficiency will be maximized and the life span of this valve extended if regular checks are made on these areas.

Applications

The Air Release Valve is very important in different industries especially where there is a need for accuracy in fluid management. In water treatment plants, airlocks are prevented with their use while irrigation systems enable smooth passage of water through them and effective control of air in HVACs. This device comes in handy when dealing with large volumes of fluids so that no interruptions can be caused by air along pipelines such as those found in Air Release Valve for Water Line.

Features and Benefits

Features:

The automatic air release valve to prevent the accumulation of air continuously.

It is resistant to corrosion and durable enough to be used in harsh environments.

Installation and maintenance are easy with minimum operational requirements.

Available in different sizes including a commonly used Air Release Valve 25mm.

It can work under various pressures and temperatures thus being applicable across many industries.

Benefits:

Prevents damage and tear of systems by effectively managing air within hydraulic systems.

Saves on costs through increased efficiency which lowers operation costs.

Keeps components running for long periods by ensuring that no air enters them hence reducing pipeline inefficiency.

This is a cheap solution whose competitiveness is evidenced by its price tag so one gets value for the money spent in buying it.

Similar Products

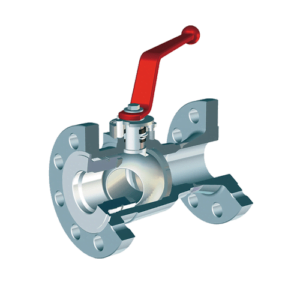

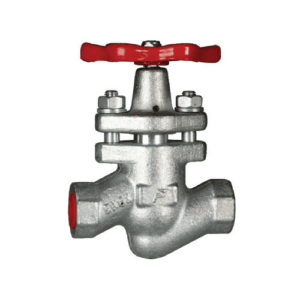

Broaden the reach of your system with synonymous products designed for total fluid control:

Air Compressor Check Valve: Stops air flowing in the wrong direction and maintains proper airflow in compressors.

Air Filter Regulator: Cleans up supply air and optimizes pressure to make machines last longer.

There are different kinds of Air Release Valves available that can handle larger pipeline systems and other specific needs.

Make sure of your system’s efficiency by installing an Air Release Valve. If there is anything else you would like us to know about or inquire more, contact us for more information. These are important because they prioritize accessibility as well as speed when it comes down to customer response.

Support and Guarantee Details

Induskart tries its best to provide excellent customer service and strong guarantees. Our support staff is here 6 days a week, from 9:30 am until 6:30 pm, Monday through Saturday to answer any questions you may have or help with anything else that may come up. For one year after the purchase of Air Release Valve, it comes with an all-encompassing warranty against defects in materials or workmanship which is further supported by us providing full installation instructions as well as operational assistance where needed along the way.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.