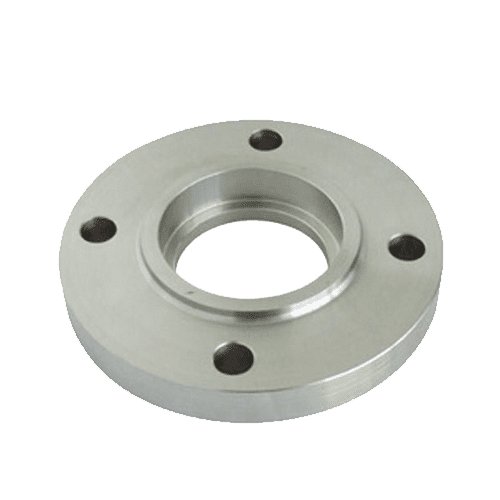

Socket Weld Flange

The [Socket Weld Flange] is an essential accessory used for the purpose of making connections in all manner of piping systems. The gasket seating area on the flange consists of a shallow socket that provides a proper and leak-proof welding connection of the pipe into the socket end. This field of applications includes systems under high pressure; among the industries normally referred to are oil and gas, chemical processing, and power generation.

Material Specifications

The [Socket Weld Flanges] are constructed using high-grade materials such as stainless steel, carbon steel, and alloy steel. Such materials are known for their characteristics of high strength, good corrosion resistance, and being of quality that is long-lasting. In particular, the flange socket is known for its potential to apply in high pressure conditions, hence serving a range of industrial utilities.

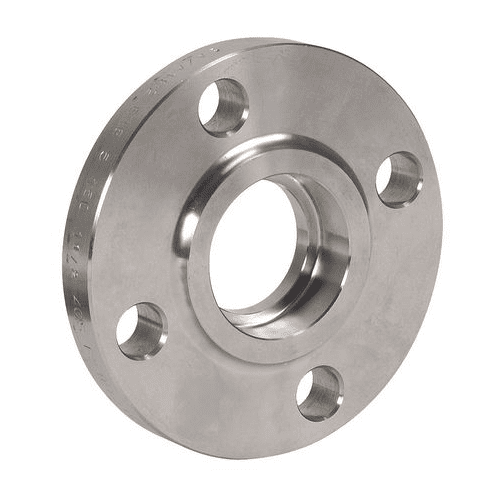

Technical Specifications

Translated into other diameters, from 1/2 inch to 24 inches, Socket Weld Dimensions Flanges are designed to meet the extreme demands imposed by absolutely any pipeline. This means that they work correspondingly with a pressure range of 1500 PSI and a temperature range of -20°C to 400°C. The provided Socket Weld Flange Dimension In Mm gives exact measurements to fit any system’s exact requirements. Generally speaking, there is a variation of the [sw flange] and [swrf flange] (Socket Weld Raised Face) developed for optimal performance in different operational contexts.

Standards and Compliance

The products meet ASTM, ASME, and ISO 9001 specifications. As the leading [Socket Weld Flange Manufacturers], we test extensively under some very strict conditions to ensure that these standards can be confirmed and our clients given the affirmative on the operational safety, reliability, and performance of our products. Certification from [Socket Weld Flange Suppliers] also translates to superior management within the company and a dedicated team to see that customers are satisfied to the highest degree.

Usage Instructions

Regular maintenance, involving checking and cleaning, will make sure the [Socket Weld Flange] performs and lasts as long as peak performance does. Remember, during installation, you should follow specifications from the [Socket Weld Flange Manufacturers] to avoid complaints like improper positioning, which can lead to malfunction. Refer to the user’s manual bundled with the product for troubleshooting and more detailed information on maintenance.

Applications

The [ Socket Weld Flange ] is a must in systems requiring leak-tight and tight applications. Its applications include oil and gas pipeline systems, chemical processing plants, and power generation industries. This variant of [ sw flange ] finds the greatest necessity to hold the system tight and not allow leakage, even under high-pressure conditions.

Socket Weld Flange will find its usefulness in high temperatures and under high pressure; it assures leak-free in the pipeline with the assurance of compact joints. The rugged design provides toughness and reliability for use in difficult service environments. Swrf flange is the most preferred flange because of its high sealing competence and hence the best in any critical industrial sector.

The [Socket Weld Flange] is designed for use in high pressure applications. The product is strong due to it being a solid connection mechanism, making it tough for use in hostile and high demanding areas. This leads to the high trust and reliance on the socket weld flange manufacturers since different socket weld flanges are produced, including custom designs based on exact requirements from industry. They are, for that very reason, trusted suppliers for precise engineering and reliable projects.

Features and Benefits

Features:

- The Advanced Sealing Technology makes the [Socket Weld Flange] closure leak-free.

- It involves a really forceful construction that’s capable of bearing high pressures and temperatures.

- The flange socket design is so versatile that it will make it easier for installation and maintenance, hence reducing downtime and labor costs.

Benefits:

- It also allows for durable building materials and design, thereby guaranteeing a long service life with little maintenance required.

- The high-level leakage resistance of the [Socket Weld Flange] increases the reliability of systems for proper functioning of critical components without damage.

- Competitive prices through socket weld flange suppliers ensure cost-effective products for businesses while receiving top-quality flanges at affordable costs.

Related Products

To ensure comprehensive system protection and efficiency, consider integrating these related products:

- [Gate Valves]: may achieve safe closure, while operational in services with elevated pressure.

- [Globe Valves]: Available for precise throttling and flow control to be used with the secure-connection features on the socket-weld flanges.

- [Strainers]: Protect socket weld flanges from debris and sediment, for an overall increase in their operational lifespan and to maintain the efficiency of flow.

Call to Action

“Request a Quote” for bulk pricing, or “Contact Us for More Information” for customized solutions. Our expert team from [Socket Weld Flange Manufacturers] is ready to assist you in selecting the ideal flange to meet your specific needs.

Support and Warranty Information

Our range of [Socket Weld Flanges], [sw flange] and [swrf flange] are covered under full warranty and proper customer support by reliable [Socket Weld Flange Suppliers]. The life cycle support shall specifically include installation support, operational support, and maintenance and troubleshooting services with respect to the new flange.