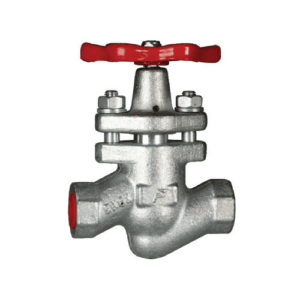

| Operator: | Hand wheel operated |

| Body (MOC): | Bronze (Gun Metal) |

| End Connection: | Screwed End / Flanged End |

Bonnet Wheel Valve

Bonnet Wheel Valve: The cover for the opening sin the body is the bonnet, and it is the second most important boundary of a pressure valve. Like valve bodies, bonnets are in many designs and models available. A bonnet acts as a cover on the valve body, is cast or forged of the same material as the body. It is commonly connected to the body by a threaded, bolted, or welded joint. During manufacture of the valve, the internal components, such as stem, disk etc., are put into the body and then the bonnet is attached to hold all parts together inside.

Related Products

Safety Valve

Valve: Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball, Butterfly, Check, Diaphragm, Gate, Globe, Knife Gate, Parallel Slide, Pinch, Piston, Plug, Sluice, etc.

Safety Valve: A safety valve is a valve that acts as a fail-safe. An example of safety valve is a pressure relief valve, which automatically releases a substance from a boiler, pressure vessel, or other system, when the pressure or temperature exceeds preset limits.

Ferrule Cock

Ferrule Cock: Ferrule Cocks incorporate a packed gland spindle and have a union outlet for connection to all ferrule bends or adaptors. RMC TPFNR Ferrules are for under pressure tapping. They incorporate a non-return gunmetal jumper valve and a high-density polyethylene tapered closing plug.

Butterfly Valve: Efficient Flow Control Solution

Butterfly valves are very similar to ball valves they also work on the phenomenon of quarter-turn rotational movement which means by moving 90 degrees it could be either turned on to fully operated or turned off to restrict the flow of fluid. This is used to transfer, regulate or stop the movement of a fluid. They are used widely in the industries such as food processing, water supply industries, water pumping, etc. they are used wherein there is a need for a broad range of flow isolation Is required. “They belong from the quarter-turn family” and they usually have large pipe diameter.

Foot Valve: Reliable Suction Control for Pumps

Valve: Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball, Butterfly, Check, Diaphragm, Gate, Globe, Knife Gate, Parallel Slide, Pinch, Piston, Plug, Sluice, etc.

Foot Valve: A foot valve is a type of check valve that is typically installed at a pump or at the bottom of a pipe line (hence the name). Foot valves act like ball check valves, but have an open end with a shield or screen over it to block debris from entering the line.

Gas Valve

A gas valve is a critical component in managing the flow and pressure of gas in heating systems, appliances, and industrial processes. This type of valve is specifically designed to ensure safe and efficient operation when handling combustible gases such as natural gas or propane. Gas valves are equipped with safety mechanisms that shut off the gas flow automatically if the pilot light goes out or if a leak is detected, preventing potential hazards. They are commonly found in residential furnaces, gas-powered water heaters, and commercial gas stoves, playing a pivotal role in both safety and functionality.

Float Valve: Automatic Water Level Control Solution

Valve: Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball, Butterfly, Check, Diaphragm, Gate, Globe, Knife Gate, Parallel Slide, Pinch, Piston, Plug, Sluice, etc.

Float Valve: Float Valve is an adverse condition which can occur at high engine speeds when the poppet valves in an internal combustion engine valve train do not properly follow the closure phase of the cam lobe profile. This reduces engine efficiency and performance and potentially increases engine emissions.

Piston Valve

Piston Valve: A piston valve is a device used to control the motion of a fluid along a tube or pipe by means of the linear motion of a piston within a chamber or cylinder. Examples of piston valves are: The valves used in many brass instruments. The valves used in pneumatic cannons.

Stop Valve: Reliable Control for Your System

Stop Valve: Stop valve is any sort of valve type that completely stops the flow of liquid flow through a pipe. Stop valves is mainly used in plumbing or industrial applications to shut off the flow of (hot or cold) water to a plumbing fixture, such as an icemaker, toilet, faucet, dishwasher etc.

Fusible Plug: Essential Safety Component for Your System

Fusible Plug: A fusible plug operates as a safety valve when dangerous temperatures, rather than dangerous pressures, are reached in a closed vessel. In steam engines the fusible plug is screwed into the crown sheet (the top plate) of the firebox, typically extending about an inch (25mm) into the water space above it.

Fire Hydrant Landing Valve: Reliable Fire Safety Solution

A Fire Hydrant Landing Valve, also known as a landing valve, is a crucial component in firefighting water supply systems. It provides an accessible means for the fire service to tap into the municipal water supply during emergencies. These valves are typically mounted on risers within buildings or on external fire hydrants, featuring a connection point for fire hoses. They are designed to withstand high pressures and allow for rapid deployment and control of water flow to combat fires effectively, ensuring quick and efficient response in critical situations.

Non Return Valve

A non-return valve, also known as a check valve, is designed to allow fluid to flow through it in only one direction. This type of valve is crucial for preventing the backflow of fluid, which could potentially cause damage or disrupt operation in systems like pumping stations, hydraulic systems, and water supply networks. Non-return valves automatically open under forward flow and close when the flow ceases or reverses, operating entirely by the pressure of the fluid being handled without the need for manual intervention. Their simple design and effective functionality make them indispensable in maintaining the integrity and efficiency of fluid control systems.

Breather Valve

A breather valve, also known as a pressure-vacuum relief valve, is designed to manage the pressure inside storage tanks that hold volatile liquids or bulk materials. These valves open at a preset pressure or vacuum level to equalize pressure, preventing the tank from over-pressurizing or undergoing vacuum conditions that could lead to structural damage. They are critical for safety in industries like oil and gas, chemicals, and pharmaceuticals, where proper pressure balance is essential for operational safety and environmental protection.

Reflux Valve

Reflux Valve: A check valve, clack valve, non-return valve, reflux valve, retention valve or one-way valve is a valve that normally allows fluid to flow through it in only one direction. Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave.

Reflux Valve Dealer and Distributor: Induskart is leading supplier and distributors in all types of Reflux Valve, Available brands are Leader, L&T, Audco, Kirloskar, Kartar, Zoloto, Sant, Sir etc. These valves are available in various types of moc like Bronze, Gun Metal, Forged Brass, Cast Steel, Cast Iron, Stainless Steel etc.

Check Valve: Reliable Backflow Prevention Solution

Valve: Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball, Butterfly, Check, Diaphragm, Gate, Globe, Knife Gate, Parallel Slide, Pinch, Piston, Plug, Sluice, etc.

Check Valve: A check valve, clack valve, non-return valve, reflux valve, retention valve or one-way valve is a valve that normally allows fluid to flow through it in only one direction. Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave.

Plug Valve: Durable Flow Control Solution

Plug Valve: Plug valves are valves with cylindrical or conically tapered “plugs” which can be rotated inside the valve body to control flow through the valve. The plugs in plug valves have one or more hollow passageways going sideways through the plug, so that fluid can flow through the plug when the valve is open.

Steam Trap: Efficient Condensate Management Solution

Steam Trap: A steam trap is a device used to discharge condensates and non-condensable gases with a negligible consumption or loss of live steam. Most steam traps are nothing more than automatic valves. They open, close or modulate automatically.

Blow Down Valve

A blowdown valve is used in boilers and pressure vessels to remove sediment and other impurities that accumulate in the bottom of the system during operation. This type of valve is essential for maintaining the efficiency and safety of the boiler by ensuring that the water quality does not degrade to a level that could cause scaling or corrosion. Blowdown valves are operated manually or automatically at set intervals to release water and accumulated solids, thereby preventing damage and maintaining the performance of the heating system. This process is crucial for prolonging the life of boilers and ensuring their safe operation.

Needle Valve

Needle Valve: A needle valve is a type of valve with a small port and a threaded, needle-shaped plunger. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates.