Components of the butterfly valve

The body

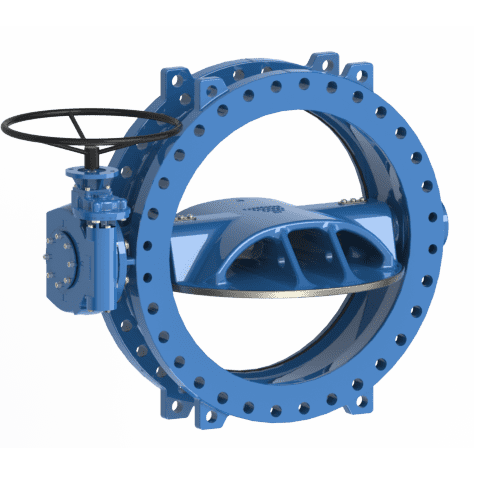

The butterfly valve body fits between the two pipe flanges. There are majorly 4 types of the body used for butterfly valve- Lug type body

- Wafer type body

- Double flanged body

- Butt-welded body type

| Name | advantages | disadvantages |

| Lug type body |

|

|

| Wafer style body |

|

|

| Double flanged body |

|

|

|

|

|

Disc

Discs are the part of butterfly valves that control the fluid flow through the valves. They could function as the gate which stops the fluid or which that allows the passing of fluid. They are present in all types of butterfly valves. The classification of butterfly valves based on disc type used could be of 4 types- Concentric disc

- Eccentric disc

- Double offset butterfly valve

- Triple offset butterfly valve

Stem

The stem is the part of the valve which connects the body of the valve to the staff. this is very small in size but yet plays a major role in the working of the valve. Without it, the functioning of the valve would not take place. The protection of stem could be classified into two types- Wetted design

- The material used here does not provide corrosion and erosion-free stem due to which they get damaged easily.

- Non-wetted design

Seat

The seat helps the valve to create a sealing effect. They run in the inner diameter of the valve. They press against the discs of the valve which collides and creates a sealing effect. They are made up of materials such as elastomers or polymers. Such material provides in carrying out better-sealing effect. They could be used either by bonding it to the body or by locking it down to it. The following are types of butterfly valves based on seat material- Soft seated

- Metal seated

Types of butterfly valves of the basis of material used

- PVC(polyvinyl chloride)

- Cast iron

- Stainless steel

- Hastelloy or nickel alloys

- Duplex stainless steel

- Actuation

- Manually operated

- Electrically operated

- Pneumatic operated

- Hydraulic operatic

- Working principle of the butterfly valve

- Selection parameter of choosing a type

- Body material

- Body type

- End connection type

- Seat material type

- Actuation to be preferred

- Other information

- Pressure ranges

- Temperature ranges

- Flow rate

- Material content

- Lightweight and compact in design

- Low maintenance costs

- Swift functioning

- Various uses

- Low cost

- Quick opening and shutting

- Various actuation

- Disc movement is affected by the flow turbulence

- Pooling sealing function

- Throttling services is limited to the flow pressure

- Not suitable with high pressure and temperature

- Chemical industries

- Mining industries

- Vacuum services

- Use for gases and compressed gas industries

- Cooling down of water

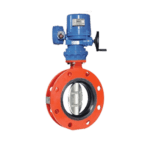

High-Performance Wafer Type Butterfly Valve for Industrial Applications

Versatile in terms of applications, the Butterfly Valve is one of the key components in the piping system that is used to regulate both flow and pressure. This type of valve is most commonly used in water treatment, chemical processing, and HVAC systems. A triple offset butterfly valve is highly valued because this type can function in high-pressure settings without a lot of wear and leakage.

Material Specifications:

Due to the tough materials it is made out of, such as stainless steel and high-grade alloys, the valve will last for a long time. The materials chosen are based on their excellent resistance to corrosion and other environmental impacts, and, therefore, they will be the same materials that will go ahead to increase the service life of the valve. It has very compact and efficient designs, making it one of the best for places that require systems where available space is at a premium.

Technical Specifications:

The Butterfly Valves are designed in sizes from 2 inches to 48 inches, which are very versatile in many applications of the piping systems. The said valves are capable of being designed to function at a maximum of 250 PSI and at temperatures from -30°C to 200°C. The valves are designed as [Wafer Type Butterfly Valve] and [Pneumatic Butterfly Valve] to meet specific operation needs. The [BF Valve] has an efficient flowing resistance mechanism and is best for high flowing.

Standards and Compliance

The Butterfly Valve conforms to international standards, including ASTM, ISO 9001, and API. One of the best [Butterfly Valves Manufacturer], we ensure that each valve manufactured in our unit conforms to these standards, thereby through these benchmarks; the buyer is assured of quality and acceptance of the product in this competitive industry.

Usage Instructions

To provide long service life, maintain your Butterfly Valve properly by inspecting it periodically and replacing the seals. Most important is the installation, to be done by a properly qualified technician so you do not fall into the regular problems of poor alignment or sealing. For general maintenance and troubleshooting consult the further detailed manual or contact our support department.

Applications

This is a critical component for many processes that require perfect flow control. These valves frequently find use in water and wastewater treatment plants because the fluid flow is controlled with a minimum pressure drop. The [Pneumatic Butterfly Valve] is a quick partner that is good in implementing automated systems with fast response and easy control. The [Wafer Butterfly Valve] is a versatile valve liked because it can easily be fitted between flanges in conditions where space is limited.

Features and Benefits

Features:

- The close dimensions of the [Wafer Butterfly Valve] allow it to be installed and maintained in extremely constricted spaces.

- The [BF Valve] model is strong and can withstand pressure and temperature fluctuations.

- As a result of this demand for operational specificity, it has become necessary for [ Butterfly Valve Manufacturers] to offer customized options.

Benefits:

- This implies a sustained, secure reliability over time, with little expense incurred by recurring replacement and maintenance.

- Its effectiveness in flow moderation and isolation helps save energy and thereby minimizes operational costs.

- Competitive prices on offers for products with butterfly valves, to offer cost-effective solutions at the same time not compromising quality for the projects.

Related Products

Consider this other related product, to maximize the performance and functionality of your valve systems:

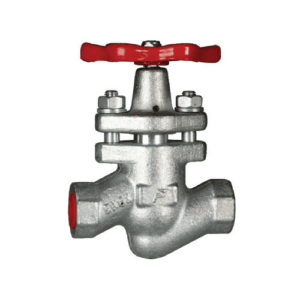

- [Gate Valves]: Applications that require a minimum flow path restriction when the valve is fully open.

- [Globe Valves]: Such valves are used for throttling service in high-pressure services when it is necessary to control the flow with good accuracy.

- [Actuators]: Make [Butterfly Valves] highly functional, especially in automated systems where remote control is very convenient.

Support and Warranty Information

Our [Butterfly Valves], from the leaders in [butterfly valve manufacturing], come supported with the broadest support and warranties available. Thorough installation instructions, unrivaled support during operation, available troubleshooting assistance, and our ability to help ensure your valve is performing perfectly will help you optimize the performance and life of your equipment.