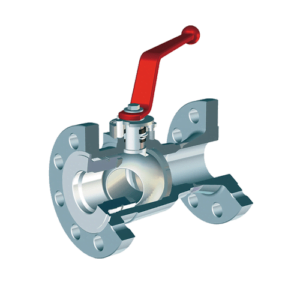

Robust Pneumatic Piston Valve for Industrial Applications

A Piston Check Valve is crucial for preventing backflow in systems that handle fluids under pressure. This valve automatically allows flow in one directioghtcn and blocks it in the opposite direction, which is essential for maintaining consistent operational pressure and protecting the system from potential damage caused by backflow. This function is particularly important in systems dealing with high-pressure liquids such as oil, gas, or steam.

Material Specifications:

The Piston Valve is made from various materials which include stainless steel and bronze among others to resist corrosion as well as wear and tear. Using sustainable materials does not only make the valve durable but it also supports efforts aimed at conserving the environment. Every single part has been selected to ensure that it remains intact under high temperatures and pressures.

Technical Specifications:

Our models of Piston Check Valves range in size between half an inch (1/2”) all through twelve inches (12”) with pressure capabilities stretching up to five thousand pounds per square inch (5000 psi). These valves are designed such that they have flanged end connections for more secure installations; besides their compact structures take up less space without compromising flow efficiency. The Piston Actuators are specially built to provide fast responsive actions within automated systems.

Standards and Compliance:

The piston valve follows the strictest international standards including ASTM and ISO 9001 which guarantees that it is produced with high quality and dependability. Manufacturers of piston check valves have also obtained certifications showing that their products can withstand tough industrial applications therefore giving confidence to buyers about its safety and effectiveness.

Usage Instructions:

To get the best out of a piston check valve, it is advisable to do regular servicing like cleaning inner parts after certain periods. Proper fixing and frequent trials must be done to achieve optimum results. For any installation involving a piston valve manufacturer’s product, one should follow instructions strictly so as not to experience common operation problems such as getting stuck or leakage. The troubleshooting tips together with more detailed maintenance guidelines can be found in the accompanying manual.

Applications:

The Piston Valve is widely used across a variety of industries including oil and gas, power generation, and chemical processing due to its robust design and reliability in controlling flow and pressure. This valve is particularly effective in applications where high viscosity fluids are present. The Angle Piston Valve is favored in systems that require angular flow direction changes, providing efficient flow management with minimal pressure drop. Piston Check Valve variants are critical in preventing reverse flow, thus protecting sensitive equipment from damage.

Features and Benefits:

Features:

Piston and Valve configurations allow for precise control over fluid dynamics, making these valves ideal for both throttling and on/off services.

The Valve in Piston design integrates the valve functionality directly within the piston mechanism, enhancing compactness and reducing potential leak paths.

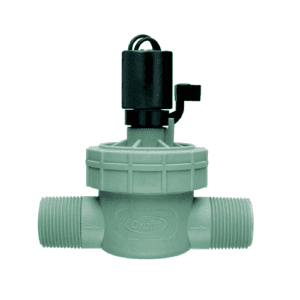

Equipped with Piston Actuators for automated control, these valves ensure consistent and reliable operation under varying conditions.

The Pneumatic Piston Valve offers rapid response times and is suitable for emergency shut-off applications.

Benefits:

Provides high durability and reliability, ensuring long-term operation with minimal maintenance required.

The Angle Piston Valve specifically allows for installation in confined spaces without compromising on flow efficiency.

Piston Check Valve setups prevent backflow and reduce the risk of hydraulic shocks in the system, thereby enhancing operational safety.

As developed by Piston Check Valve Manufacturers, these valves are engineered to meet stringent industry standards for safety and performance.

Related Products:

To optimize your valve system further, consider incorporating these related products: Ball Valves: Provide a perfect complement for quick shut-off capabilities alongside your Piston Valve setups.

Globe Valves: Ideal for precise flow control, working in tandem with the modulating abilities of piston-based designs.

Safety Valves: Essential for pressure relief, these valves can be integrated into systems to ensure safety under excess pressure conditions.

Enhance your fluid control systems with our durable and efficient Piston Valve. Our skilled team is ready to assist you in selecting the perfect valve solutions for your needs.

Support and Warranty Information:

All our Piston Valves, including specialized Pneumatic Piston Valve models, come with comprehensive support and a robust warranty. We offer detailed installation instructions, operational support, and troubleshooting services provided by expert Piston Valve Manufacturer teams. Our products are designed to deliver exceptional performance and reliability, ensuring peace of mind for all users.