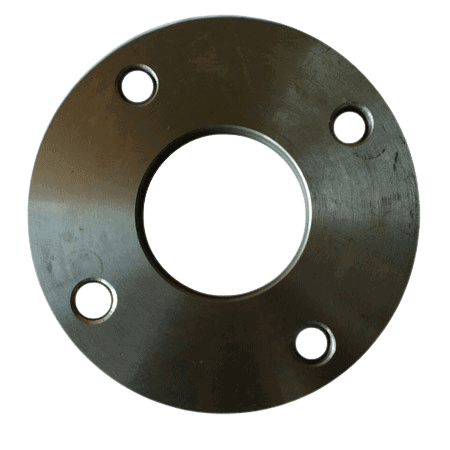

Carbon Steel Flanges

The [Carbon Steel Flanges] are used in some of the widely used piping systems in the industry, which connects the pipes, valves, pumps, and other equipment. They make a tight and leak-proof joint, which is vital in many industries—from processing oil and gas, to the chemical processing industries, and even power generation. Their robust nature is ideal for handling high-pressure and high-temperature jobs.

Material Specifications

Specifications on these [Carbon Steel Flanges] are done on the manufactured top-quality carbon steel, which has proved to exhibit exceptional strength and toughness features. Material selection ensures that these flanges can withstand hard conditions like high pressure and temperature. Types available here are: Carbon Steel Plate Flanges and Carbon Steel Forged Flanges. Each of these types has a reputation for its strong-built and long service life.

Technical Specifications

We produce products ranging from 1/2 inches to 48 inches in [Carbon Steel Flanges]. This in plain text means meeting all pipeline size requirements. Our products are designed to work on pressures up to 2500 PSI and temperatures rated at -29°C to 425°C. These devices are available in many forms – one among them is the [CS Flange], and the [steel flange] is designed to deliver top-quality performance in specified areas.

Standards and Compliance

Every [Carbon Steel Flange] that we offer meets the standards set by international regulatory bodies such as ASTM, ASME, and ISO 9001. We ensure that our [Carbon Steel Flanges] meet after testing. The ISO 9001 certification is also part and parcel of the certification, which is proof of the quality management and customer service excellence. Our [Carbon Steel Flanges Suppliers] offer certification signifying quality management system compliance, and customer service excellence.

Usage Instructions

The Carbon Steel Flanges ensure proper performance and long life with inspections and regular clean-ups. Installation shall be done under the supervision of [Carbon Steel Flanges Manufacturers in India] to avoid common errors, including the misplacement of the device, which might result in its weight loss. If you need assistance with troubleshooting and need more detailed information about the system’s maintenance, please refer to the user manual or contact our technical department.

Applications

The [Carbon Steel Flange] plays a vital role in applications that require maintenance-free leak-free connection between innumerous components. It finds great usage in oil and gas pipelines, chemical processing industries, and power-generation plants. The [CS Flange] is a necessity for the system’s integrity to avoid leakages in any system carrying such a high pressure and temperature.

[Carbon Steel Flange] helps in water and waste management systems with leak-free pipelines. It has rugged construction to last longer and function efficiently in any kind of environment. [Carbon Steel Forged Flanges] are a boon since these boast great mechanical capabilities that are great for critical industrial applications.

A [Carbon Steel Plate Flange] is duly designed to meet heavy-pressure work. The rugged mechanism ensures long life and high strength even in demanding situations. [Carbon Steel Flanges Manufacturers in India] have produced a huge variety of Carbon Steel Flanges according to the specific requirements of industries in order to make this adaptability and its ability to provide solutions with accuracy the reason for selecting it for the top choice for the project.

Features and Benefits

Features:

- High-technology sealing used in the [Carbon Steel Flange] ensures perfect closing without any leakage.

- Greatly rugged construction of the [Carbon Steel Forged Flanges] for use in severe climatic conditions.

- The highly flexible designs of the [Carbon Steel Plate Flanges] allow for easy installation and quick servicing, which in turn reduces system downtime and labor costs.

Benefits:

- The use of such construction materials and design meeting high standards for long-term performance means long service life and reduced maintenance needs.

- Systems are leak-proof and improve the reliability of the systems, providing real protection for sensitive equipment from damage.

- Competitive prices of the Carbon Steel Flange Price against prices of other systems make the devices affordable and efficient for business needs.

Related Products

To ensure comprehensive system protection and efficiency, consider integrating these related products:

- [Gate Valves]: Allow for robust shut-off needs in high-pressure applications.

- [Globe Valves]: Allow for precise throttling and flow control needs that marry up with the secure connection properties of carbon steel flanges.

- [Strainers]: Use to safeguard carbon steel flanges against sand and silt, normally found in fluids, to ensure the highest service life, while keeping rates of flow high.

Call to Action

“Request a Quote” for bulk pricing, or “Contact Us for More Information” for customized solutions. Our expert team from [Carbon Steel Flanges Manufacturers In India] is ready to assist you in selecting the ideal flange to meet your specific needs.

Support and Warranty Information

Our [Carbon Steel Flanges], which include the [Carbon Steel Plate Flanges] and [Carbon Steel Forged Flanges], enjoy a full warranty of workmanship and materials, coupled with full customer support from reliable [Carbon Steel Flanges Suppliers]. We offer installation guidelines control, operational support, and troubleshooting services to guarantee optimal performance of the flange over its service life.

What are the applications of flanges?

- Petrochemical industries

The flanges are used to connect pipes and valves. They are used to connect pipes with gaskets. This helps in the transfer of material used in petrochemical industries that have high pressure and temperature. It provides easy inspection of the material by eyes. They could be cleaned easily.

- Automobile industry

They are used in vehicles to connect the engine and the transmission.

- Electronics

They are used in many electronic devices to join various parts. For example, the flanges are used to connect the glass and the lens of the camera.

What are carbon steel flanges?

The cast carbon steel flanges or the CS flanges are one of the types of materials that are used to make flanges. CS FLANGES or Carbon Steel flanges are one of the types of flanges based on the material of manufacturing flanges.

The Various Types of CS FLANGES or Carbon Steel Flanges

- Weld Neck CS Flanges

Weld Neck CS Flanges have an outburst neck attached to the top of the flanges. They are also known as high hub flange or tapered hub flange. Such flanges are used to reduce the pressure of fluid in the bottom of the flange. They are used in high temperature as well as in low temperature withstanding the high pressure. They provide commendable stress distribution through the tapered hub, which helps the flanges to work more efficiently. They could handle pressure up to 5000PSI.

What are the applications of Weld Neck Flanges?

- Oil and gas pipes

- Vehicle rims:- car rims, motorcycle rims, chain rims,etc

- Reinforcing of steel

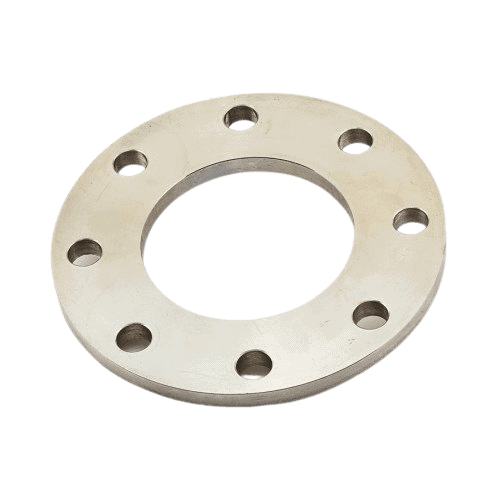

- Slip-On CS flanges

Slips on flanges are placed on the end of the pipe with a flange face extending from the end of the pipe by sufficient distance to apply a welded beard to the inner diameter. They are also known as “SO” flanges. The diameter and size of the slip-on flange are bigger than the pipe which helps it to slip over the pipe with internal design. The top and bottom of these flanges could be connected easily by welding them to the pipe. They are majorly used for low-pressure pipes and are considered to be suitable for fluid material.

What are the applications of slip on flanges?

- Cooling water lines

- Fire fighting water lines

- Low-pressure air compressor

- Threaded CS flanges

Threaded flanges are very similar to the slip-on flanges but the major difference is in the size the slip-on face flanges have a larger diameter than pipes whereas the threaded flanges have a diameter matching the pipes. They are used for pipes with high pressure and small diameters. the main benefit of threaded flanges is that they could be installed without welding.

What are the applications of threaded flanges?

- Petrochemical industries

- Chemical industries

- Textile industries

- Reducing CS flanges

The reducing flanges are used when the pipe size is not the same they keep on changing.These flanges generally come in neck flanges that are blind, slip-on, threaded, and weld. They are available in all pressure classes and offer an excellent alternative to connecting two different pipe sizes. The reducing flanges consist of 2 bores one which has a fixed diameter and the other one with a smaller diameter.

What are the applications of reducing flanges?

- Used for the pipe to pipe connections

- Food processing industries

- Paper and pulp industries

| Name | Advantages | disadvantages |

| Weld neck flanges |

|

|

| Slip on flanges |

|

|

| Threaded flanges |

|

|

| Reducing flanges |

|

|

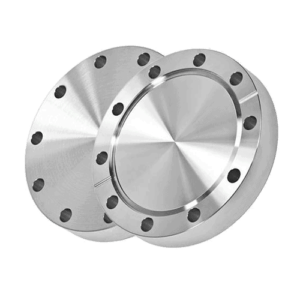

What are the types of Carbon Steel flanges based on flange finish and facing types?

- Flat face flange (FF)

A flat face flange has a flat top and bottom unlike a few having ridge-like elevated or ring type joint flange. It has a gasket on the surface which allows full contact between the entire matting face. They are used in low-pressure and low-temperature surroundings.

What are the applications of flat face flanges?

- Low-pressure water supply pipes

- Filtration plant

- Water treatment plants

- Raised face flange(RF)

These are the most common flange face type used. It’s called a raised face because it has a raised surface above the bolting circle where the gasket is placed. Sealing this type of flange face is accomplished by compressing a soft, flat, or semi-metallic gasket between mating flanges in the raised area of the flanges. They are suitable for high as well as low temperatures. The flange diameter is directly related to the pressure that is higher the pressure larger the diameter.

What are the applications of raised face flanges?

- Oil and gas pipelines

- Chemical industries

- Automobile industries

- Male and female flanges(M & F)

Male and female flanges are the type that fits in one another. the male flanges stretch more than the usual flange face. The female flange has a depression in its nose which attaches with the male flange.

The female flange is supposed to belong whereas the male flange is supposed to be wide. Male and female flanges tend to have more sealing abilities and are more reliable for positioning.

What are the applications of male and female flanges?

- Used in the piping of same material

- Oil and gas pipelines

- Plumbing

- Ring joint flange(RJT)

The ring joint flange is used when metal to metal seal is required. They are highly used and suitable for high pressure and high-temperature operations. They could even function above 800 degrees Celsius.The ring joint flange features a circular groove to accommodate a ring joint gasket.

As the two ring joint flanges are bolted together and then tightened, the applied bolting force deforms the gaskets inside the flange the groove creates a very tight metal-to-metal seal.

What are the applications of ring joint flanges?

- Furnaces

- Petrochemical industries

- Chemical industries

| Name | Advantages | Disadvantages |

| Weld neck flanges |

|

|

| Raised face flanges |

|

|

| Male and female flanges |

|

|

| Ring joint flanges |

|

|

What are the advantages of Carbon Steel flanges?

- They are lightly weighted comparing to other hard metal flange types

- Greatly affordable, they are a lot cheaper than other metals such as titan steel or stainless steel.

- They are very malleable; they could be given a reshape or could be made in any shape or type easily.

- They are very durable

- They are good machinable alloy

- What are the disadvantages of Carbon Steel flanges?

- They are comparatively less strong and are not recommended for high pressure and high temperature.