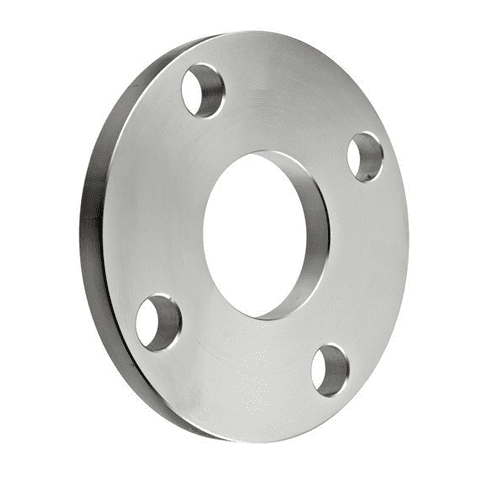

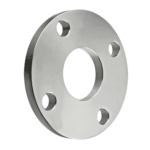

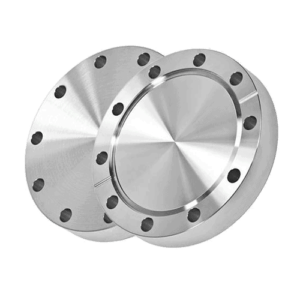

Flat Face Flange

A [Flat Face Flange] is one of the key connecting elements of many piping systems in connecting pipelines, valves, and some extra equipment. It is designed for a smooth leak-tight joint for system integrity under all pressures. This flange is applied in such industries as oil and gas, chemical processing, and water treatment because of their durability and reliability.

Material Specifications

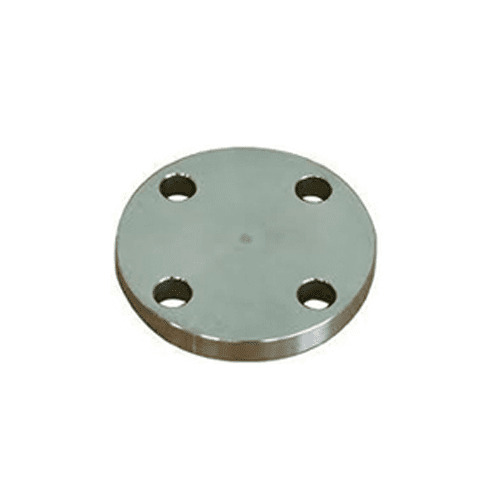

Our [Flat Face Flanges] have been made with strong, corrosion-resistant materials that can serve you for a long time. In fact, the [Flat Face Blind Flange] is noted for its ability to completely shut off a pipe, making it perfect for a wide range of industrial applications.

Technical Specifications

These come in sizes 1/2 inch to 48 inches, according to size requirements of a pipeline. The compensating ability of these to different pressures of up to 1500PSI and temperatures within -20°C to 400 °C is remarkably high. [Flat Face Flange Dimensions] are correctly engineered and designed to suit a few systems specifications; most common is to [Flat Face Blind Flange] and other related [raised face to flat face flange connection] that is meant to maximize the performance of use under varied operational environmental.

Standards and Compliance

We make all flanges in adherence to international standards, which include ASTM, ASME, and ISO 9001. As a leading manufacturer of flanges, the pieces we offer are tested to meet and even exceed the stipulated standards, thereby providing our customers with confidence in terms of safety, reliability, and performance. Supplies of a [Flat Face Flange Supplier] indicate compliance with quality management and excellence in servicing available to the customer; certification of compliance is formalized.

Usage Instructions

Please perform periodic inspection applications, clean, and carefully inspect for long and proper trouble-free service. Install according to design by [Flat Face Flange Manufacturers] to save from the basics problems, eg. wrong placements, that could affect the performance largely. For detailed troubleshoots and maintenance, check the user manual or call our technical assistance team.

Applications

Main areas where [Flat Face Flange] is put into practical application are in systems that demand connections which are extremely tight and leak-proof. In certain applications, the flat-face flange is widely used besides oil and gas pipelines: in the chemical processing plant, water treatment plant, etc. The [Flat Face Blind Flange] version keeps system integrity and totally prevents any leakage even at high pressure.

They have a significant place in HVAC for reliability in connection and sealing pipe leakages. Its robust design assures durability and reliability. The flange connection with a [raised face to flat face] joint is greatly appreciated for high flexibility joining flanges of a various type, which makes it perfect for complex piping systems.

The [Flat Face Flange] is designed to offer a tight connection within a high-pressure system. The strong mechanism makes it durable in the end; thus, it is apt to be used in intensive workplaces. [Flat Face Flange Manufacturers] have the widest range of flat face flanges, with customizable flat face flange varieties for particular industrial applications. Such adaptability will place them as the preferred suppliers for projects that require precision engineering and reliability.

Features and Benefits

Features:

- The advanced sealing technology applied to the [Flat Face Flange] surface ensures a tight closure without any leakage.

- It is so heavily built and constructed for tough applications with high pressure and temperature.

- This piece has been designed for versatile placement, allowing for subsequent maintenance to be easily carried out, thus reducing downtime and labor costs.

Benefits:

- The usage of sturdy design and construction materials results in the development of a sturdy construction; therefore, long life and rare need for frequent maintenance.

- The sealing ability of the [Flat Face Flange] also helps increase the performance and reliability of a system, hence protecting the most critical components from compromise.

- The competitive rate of flat face flange assures the business community of cost-effective and top-quality flanges at cheap prices.

Related Products

To ensure comprehensive system protection and efficiency, consider integrating these related products:

- [Gate Valves]: Provide strong sealing means for services that are under heavy pressure.

- [Globe Valves]: Provide accurate throttling and regulation of flow to the safe connection feature of flat face flanges.

- [Strainers]: Protect flat face flanges from debris and sediment, extend the operational life of equipment, and maintain a high level of flow efficiency.

Call to Action

“Request a Quote” for bulk pricing, or “Contact Us for More Information” for customized solutions. Our expert team from [Flat Face Flange Manufacturers] is ready to assist you in selecting the ideal flange to meet your specific needs.

Support and Warranty Information

Our range of [Flat Face Flanges], [sw flange], and [swrf flange] are covered under full warranty and proper customer support by reliable [Flat face Flange Suppliers]. The life cycle support shall specifically include installation support, operational support, and maintenance and troubleshooting services with respect to the new flange.