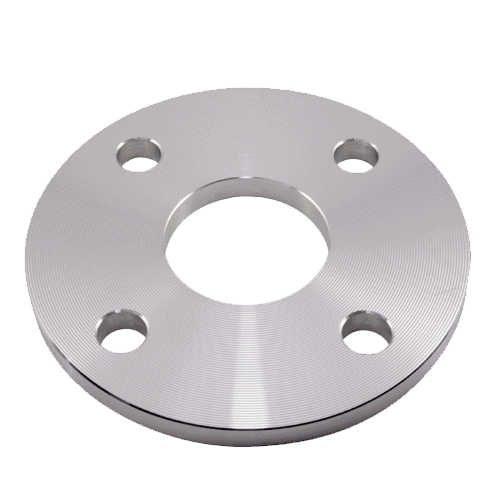

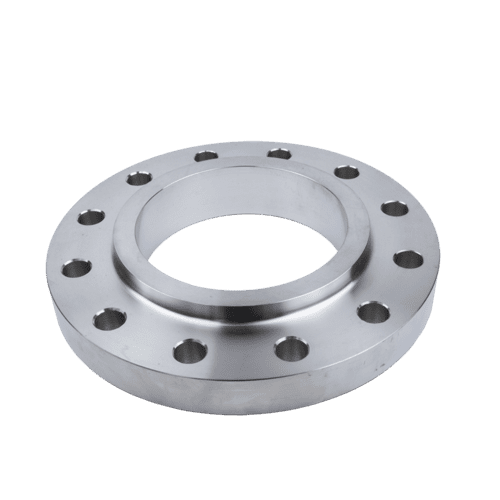

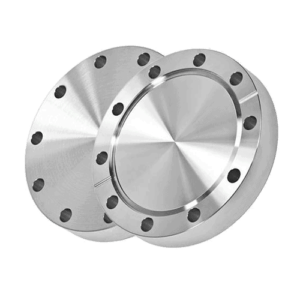

Slip On Flange

The [Slip On Flange] is a multi-purpose fitting designed to join pipes into a multitude of piping systems. It is used by sliding the flange over the pipe, then welding it from both inside and outside to provide a rigid and firm connection without leaks. This flange finds use in great quantities in various industries like oil and gas, chemicals, and water treatment for its easy installation and cost-efficient nature.

Material Specifications

Our [Slip On Flanges] are constructed from top-quality metals that include stainless steel, carbon steel, and alloy steel. Such materials guarantee great strength, resistance against corrosion, and increased durability. The [sorf flange] (Slip On Raised Face) is especially noted for its superior leak-proof quality, and is suitable for high-pressure and high-temperature applications.

Technical Specifications

The [Slip On Flanges] can come in variable dimensions from half an inch to 48 inches to suit various pipeline needs. They can take pressures of up to 1500 PSI and have a working temperature from -20°C to up to 400°C. Signature sizes include the [Slip On Flange Class 150], [Flange Slip On 150] and [Slip On Flange Dimensions], and they are all pre-calibrated to provide optimal performance despite the nature of their operational context.

Standards and Compliance

Each Slip On Flange is engineered to meet international standards such as ASTM, ASME, and ISO 9001. As the best Slip On Flange Manufacturers, we therefore guarantee that each product is put through the wringer so as to meet these standards and in order to give our buyers the most excellent assurances with regard to their safety, reliability, and performance. Certification from Slip On Flange Suppliers means that quality management and customer service par excellence have been adhered to.

Usage Instructions

Regular maintenance including inspection and cleaning are highly recommended for optimal performance and long life of end connections. Installing them as per the specifications provided by the [Slip On Flange Manufacturers] would help avoid the common issues, such as poor positioning, which affects the functioning of the products. Please refer to the owner’s manual for troubleshooting and more maintenance tips or visit our technical support for any assistance.

Applications

The [Slip On Flange] is responsible for connecting applications that require a strong, tight fitting connection without leakage. Consequently, it is used in oil and gas lines, chemical processing plants and water treatment facilities. Slip On Flange Class 150 is well suited for leading uses which have high pressure as any slight loss of either liquid or gas would be catastrophic.

[Slip On Flange] has been one of the most effective mechanisms in HVAC system because it provides a leak free connection while at the same time preventing any leakage within the pipeline. It is designed and constructed with a strong physical structure to serve for long in any environment. This [Flange Slip On 150] will be appropriate if you are working on large pipes with big diameters; it has heavy duty industries.

[Slip On Flange] is most admired due to its tight sealing in high-pressure operations. The robust mechanism ensures durability and reliability, which is suitable in harsh and demanding environments. Slip On Flange Manufacturers offer the following benefits: Flexibility to offer a high range of slip on flanges, including custom-made solutions to meet your precise industrial requirement. This flexibility qualifies them as one of the most preferred manufacturers for projects that must guarantee precise engineering and reliability.

Features and Benefits

Features:

- Employing superior sealing technology in Slip On Flange to ensure there is no form of leakage.

- The sorf flange is designed with a robust construction in [Slip On Flange Class 150] for high pressure and temperature applications.

- The flexible design of the sorf flange makes the handling easier during installation and maintenance, reducing downtime and labor costs.

Benefits:

- Long service life and reduced maintenance requirements due to construction from durable materials and design.

- Leak prevention efficiency enhances system reliability and protects vital elements from damage and reduces the requirement for maintenance activities.

- Competitive Slip On Flange price from Slip On Flange suppliers ensures cost-effectiveness for businesses while maintaining high-quality raw material at affordable rates when looking at the long-term impact.

Related Products

To ensure comprehensive system protection and efficiency, consider integrating these related products:

- [Gate Valves]: Provides robust shut-off capabilities for high-pressure environments.

- [Globe Valves]: Offer accurate throttling and flow regulation capability, combined with the secure connection role of slip on flanges.

- [Strainers]: Protects debris and sediment from the slip on flanges, extending their service life and maintaining their flow efficiency.

Call to Action

“Request a Quote” for bulk pricing, or “Contact Us for More Information” for customized solutions. Our expert team from [Slip On Flange Manufacturers] is ready to assist you in selecting the ideal flange to meet your specific needs.

Support and Warranty Information

Our [Slip On Flanges], including the [Slip On Flange Class 150] and the [Flange Slip On 150], are covered by a comprehensive warranty and full customer support by trusted [Slip On Flange Suppliers]. We provide installation guidance, operational support, and troubleshooting services to ensure your flange performs optimally over its service life.