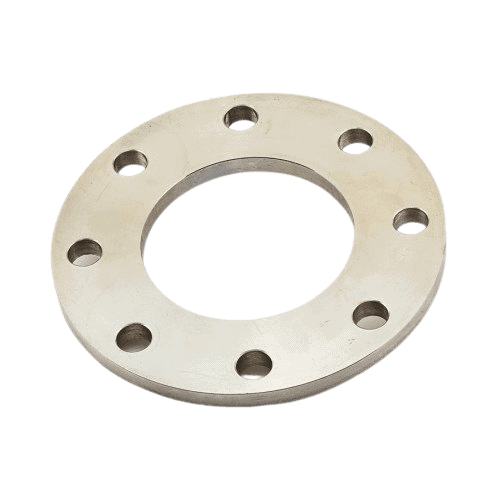

SS Flange

It is considered a very important component that is used for a variety of piping systems to bind pipes, valves, pumps, and other equipment in order to make the piping system function properly. This ensures a tight and leak-free seal, which is very critical in the oil and gas industry and others dealing with the handling of water. It is liked best for the ruggedness and corrosion resistance in very tough environments.

Material Specifications

[SS Flanges] that we produce are manufactured using the best available [304 stainless steel flanges] in the market, having excellent corrosion resistance and long-lasting life. The choice of material used ensures the flanges withstand high temperatures and work under pressure, consequently leading to their use in several different types of industrial applications. The [flange ss 304] is known for the eco-friendly nature, given the ability to be reused and the general adherence to set environmental regulations.

Technical Specifications

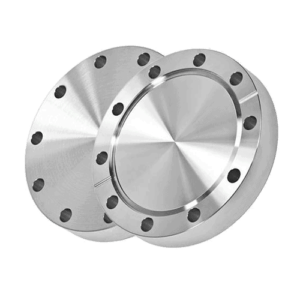

This [SS Flange] comes in varying sizes as per the need, ranging between 1/2 inches and 48 inches, and fits different requirements for the pipeline. They can work at a pressure of up to 600 PSI and temperatures between -10°C to 200°C. Flanges can be obtained in types like [blank flange], [cp flange], and [pipe flange] with each made to offer flawless performance depending on the operational context. The [304 stainless steel flanges] are known for being one of the most extremely responsive types and easy to install.

Standards and Compliance

All [SS Flanges] are manufactured within the ASTM standards and are certified under ISO 9001, API. Being the leading [SS Flanges Manufacturers in India], we carry out wide-ranging exams on our items to ensure that they meet standard quality and customer satisfaction. Certification from [SS Flanges Supplier] assures quality management and excellence in customer service.

Usage Instructions

The [SS Flange] should undergo routine maintenance, including inspection and cleaning, in order to remain at peak performance for a longer lifespan. When installing, make sure that the installation company is operating under the instruction of the [SS Flanges Manufacturers in India] to avoid minor problems, such as the wrong installation position, which may greatly affect the operation. In case of any problems, refer to the user manual or contact the technical support team for feedback on further maintenance.

Applications

The [SS Flange] is an absolute necessity to have a secure, leak-proof connection system for all needed applications. For these, in a system such as the [SS Flange Water Pump], this is greatly used to prevent leakage and push fluid perfectly. The [SS Flange] variant is of utmost assistance in the chemical processing plant in maintaining the integrity of the system and avoiding contamination.

The [SS Flange] is a necessary fix to avoid leaks that would be quite a bother for safety and reliable operations across industries. It works extremely well with applications in water and wastewater management systems, power generation, and process industries. It is sturdy in construction, and hence, the [SS Flange] can be installed in any place and still perform to the best of its abilities.

This [SS Flange] type is designed in a way that a high-pressure condition is given to have a secure connection system. Its robust feature guarantees durability and reliability, making it a go-to in harsh and challenging conditions. [SS Flanges Manufacturers in India] have a wide range of SS flanges, which are inclusive of tailor-made solutions to fit the needs of various industries; hence, these manufacturers offer the best option for precision engineering and reliability in projects.

Features and Benefits

Features:

- The advanced sealing technology provided with the [SS Flange] guarantees a perfect closure without any leakage.

- The high-pressure condition in this system gives a secure connection system.

- This versatile design of [SS flange] helps in easy installation and maintenance, which in return saves time along with the labor costs.

Benefits:

- Long service life and lower maintenance requirements are a result of the material type and overall design.

- The [SS flange] is a very effective item for leak prevention, which in turn allows assuring systems’ reliability, as well as host equipment, is safeguarded from damage.

- Competitive [SS flange price] is guaranteed from [SS flanges supplier] for business profitability, as only high-quality flanges are supplied at the most reasonable price.

Related Products

To ensure comprehensive system protection and efficiency, consider integrating these related products:

- [Gate Valves]: This feature is important for strong shut-off in high-pressure environments.

- [Globe Valves]: For precise throttling and flow regulation, this valve is a good partner with the secure connection that the SS flange offers.

- [Strainers]: It helps consumers avoid debris and sediment, thus protecting SS flanges, while it increases its life and flow efficiency.

Call to Action

“Request a Quote” for bulk pricing, or “Contact Us for More Information” for customized solutions. Our expert team from [SS Flanges Manufacturers in India] is ready to assist you in selecting the ideal flange to meet your specific needs.

Support and Warranty Information

Our [SS Flanges], such as the [blank flange] and [cp flange], come with a full warranty and excellent customer support from the most trusted name in [SS flanges suppliers]. We have a team that offers installation guidance, operational support, and troubleshooting services, ensuring your flange works properly for the entire service life.

What are the applications of flanges?

- Petrochemical industries

The flanges are used to connect pipes and valves. They are used to connect pipes with gaskets. This helps in the transfer of material used in petrochemical industries that have high pressure and temperature. It provides easy inspection of the material by eyes. They could be cleaned easily.

- Automobile industry

They are used in vehicles to connect the engine and the transmission.

- Electronics

They are used in many electronic devices to join various parts. For example, the flanges are used to connect the glass and the lens of the camera.

What are stainless steel flanges?

Stainless steel flanges or SS flanges are one of the types of materials that are used to make flanges. SS FLANGES or Stainless Steel flanges are one of the types of flanges based on the material of manufacturing flanges.

The Various Types of SS FLANGES or stainless Steel Flanges

- Weld Neck SS Flanges

Weld Neck SS Flanges have an outburst neck attached to the top of the flanges. They are also known as high hub flanges or tapered hub flanges. Such flanges are used to reduce the pressure of fluid in the bottom of the flange. They are used in high temperatures as well as in low temperatures withstanding the high pressure. They provide commendable stress distribution through the tapered hub, which helps the flanges to work more efficiently. They could handle pressure up to 5000PSI.

What are the applications of Weld Neck Flanges?

- Oil and gas pipes

- Vehicle rims:- car rims, motorcycle rims, chain rims, etc

- Reinforcing steel

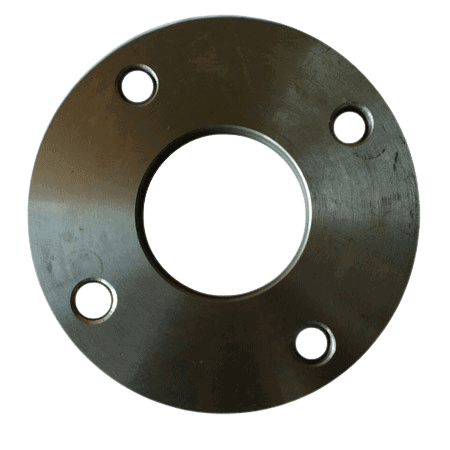

- Slip-On SS flanges

Slips on flanges are placed on the end of the pipe with a flange face extending from the end of the pipe by a sufficient distance to apply a welded beard to the inner diameter. They are also known as “SO” flanges. The diameter and size of the slip-on flange are bigger than the pipe which helps it to slip over the pipe with internal design. The top and bottom of these flanges could be connected easily by welding them to the pipe. They are majorly used for low-pressure pipes and are considered to be suitable for fluid material.

What are the applications of slip-on flanges?

- Cooling water lines

- Firefighting water lines

- Low-pressure air compressor

- Threaded SS flanges

Threaded flanges are very similar to the slip-on flanges but the major difference is in the size the slip-on face flanges have a larger diameter than pipes whereas the threaded flanges have a diameter matching the pipes. They are used for pipes with high pressure and small diameters. the main benefit of threaded flanges is that they could be installed without welding.

What are the applications of threaded flanges?

- Petrochemical industries

- Chemical industries

- Textile industries

- Reducing SS flanges

The reducing flanges are used when the pipe size is not the same they keep on changing. These flanges generally come in neck flanges that are blind, slip-on, threaded, and welded. They are available in all pressure classes and offer an excellent alternative to connecting two different pipe sizes. The reducing flanges consist of 2 bores one which has a fixed diameter and the other one with a smaller diameter.

What are the applications of reducing flanges?

- Used for the pipe to pipe connections

- Food processing industries

- Paper and pulp industries

| Name | Advantages | disadvantages |

| Weld neck flanges |

|

|

| Slip on flanges |

|

|

| Threaded flanges |

|

|

| Reducing flanges |

|

|

What are the types of stainless steel flanges based on flange finish and facing types?

- Flat face flange (FF)

A flat face flange has a flat top and bottom unlike a few having ridge-like elevated or ring-type joint flanges. It has a gasket on the surface which allows full contact between the entire matting face. They are used in low-pressure and low-temperature surroundings.

What are the applications of flat-face flanges?

- Low-pressure water supply pipes

- Filtration plant

- Water treatment plants

- Raised face flange(RF)

These are the most common flange face type used. It’s called a raised face because it has a raised surface above the bolting circle where the gasket is placed. Sealing this type of flange face is accomplished by compressing a soft, flat, or semi-metallic gasket between mating flanges in the raised area of the flanges. They are suitable for high as well as low temperatures. The flange diameter is directly related to the pressure that is higher the pressure larger the diameter.

What are the applications of raised face flanges?

- Oil and gas pipelines

- Chemical industries

- Automobile industries

- Male and female flanges(M & F)

Male and female flanges are the type that fits in one another. the male flanges stretch more than the usual flange face. The female flange has a depression in its nose which attaches to the male flange. The female flange is supposed to belong whereas the male flange is supposed to be wide. Male and female flanges tend to have more sealing abilities and are more reliable for positioning.

What are the applications of male and female flanges?

- Used in the piping of the same material

- Oil and gas pipelines

- Plumbing

- Ring joint flange(RJT)

The ring joint flange is used when metal to-metal seal is required. They are highly used and suitable for high-pressure and high-temperature operations. They could even function above 800 degrees Celsius.

The ring joint flange features a circular groove to accommodate a ring joint gasket. As the two ring joint flanges are bolted together and then tightened, the applied bolting force deforms the gaskets inside the flange the groove creates a very tight metal-to-metal seal.

What are the applications of ring joint flanges?

- Furnaces

- Petrochemical industries

- Chemical industries

| Name | Advantages | Disadvantages |

| Weld neck flanges |

|

|

| Raised face flanges |

|

|

| Male and female flanges |

|

|

| Ring joint flanges |

|

|