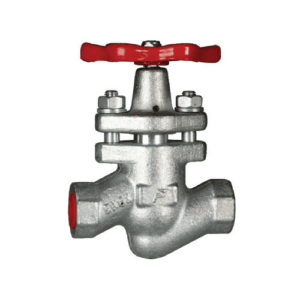

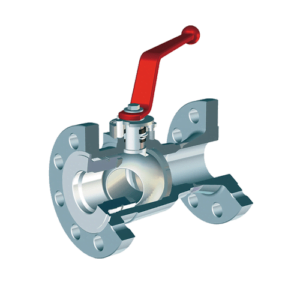

High-Performance Blow Off Valve for Turbo and Boiler Applications

A Blow-Off Valve (BOV) is an important valve designed to release pressure developed in excess in the systems of boilers and turbocharged engines, protecting the same from any pressure spikes and enhancing performance. Being an important part in fine-tuning vehicles and/or keeping a boiler functional within industrial setups, the Turbo Blow Off Valve and Boiler Blow Off Valve Manufacturer take care of the integrity and optimum running of any system.

Material Specifications:

The fact that the Blow Off Valves are made from stainless steel and aluminum allows the product to have superior resistances to high temperature and corrosion. This ensures we have an environmentally friendly product made from sustainable methods without affecting the durability and performance of the product.

Technical Specifications:

- Size options from 25mm to 75mm

- Pressure handling up to 30 PSI for turbo applications and up to 150 PSI for boilers

- Temperature tolerance from -20°C to 250°C

Features include quick release and re-circulating options, suitable for diverse installation environments

- These specifications ensure that our [Blow Off Valve Plumbing Manufacturer] products can handle the rigorous demands of both automotive and industrial applications.

Standards and Compliance

Our Blow Off Valves are manufactured according to the ASTM and ISO 9001 international standards. We are certainly one of the best, and our clients will be content with the trust in our pressure management solutions.

Usage Instructions

To maximize the effectiveness and lifespan of your [Blow Off Valve], follow these usage tips:

- Check the valve for leaks and wear from time to time; replace parts as needed.

- Proper installation is needed to prevent operational problems, which shall be in accordance with the manufacturer’s specifications.

- Periodically check turbo applications for signs of loosening or damage of the joint and mounting.

- Keep the boilers in the system according to the boiler schedule, and these would be kept operational in a high-pressure situation.

- For further, more detailed advice, refer to the manufacturer’s installation and maintenance manual, or contact our expert support team in writing.

Applications

The [Blow Off Valve] is crucial in a variety of settings due to its functionality in pressure release and system protection:

- Automotive Turbo Systems: The [Turbo Blow Off Valve] is simply a piece of hardware used in turbocharged engines to release the unused boost pressure either into the atmosphere or back into the system; this allows for the prevention of surge in the compressor and increases its life expectancy.

- Industrial Boilers: It manufactures valves critical in the management of steam pressure; not bringing the steam pressure into over-pressure conditions, in which case the equipment will fail.

- Plumbing Systems: [Blow Off Valve Plumbing Manufacturer] offers solutions that are critical in residential and commercial plumbing systems to control water pressure and prevent damage due to pressure build-up.

Features and Benefits

Features

- Pressure Regulation: It offers much-needed relief in systems in which added pressure can be risky for equipment and safety.

- Enhanced Performance: It maintains high engine performance and efficiency by controlling the boost pressure in turbo systems.

- Durability and Reliability: Made from materials that can withstand high pressures and temperatures, ensuring long-term reliability and performance.

Benefits:

- Safety: Pressure control and limitation prevent potential system failures and the associated hazards.

- Maintenance Reduction: It serves to reduce the frequency and cost of maintenance by relieving the undue stress that is put on the components of the system.

- Efficiency: Enhances the operational efficiency of systems by operating under the optimal possible pressure ranges of systems.

Related Products

For a comprehensive system management, consider these complementary products:

- [Pressure Relief Valves]: Ensure greater safety by releasing pressure when it is above the set limits of the system.

- [Check Valves]: This allows the passage of liquid or gas in only one direction, which prevents a reverse flow that might cause inefficiency in the system.

- [Control Valves]: Regulates the flow and pressure of a system, hence a more complete solution for control.

Support and Warranty Information

Our Boilers Blow Off Valves carry full warranty and full customer support, including any of the special models like the Turbo Blow Off Valve or even the Boiler Blow Off Valve. In fact, a guide for installation, operating support, and trouble-shooting services are also extended for ensuring that the valves work flawlessly to keep the system in an intact, working condition.