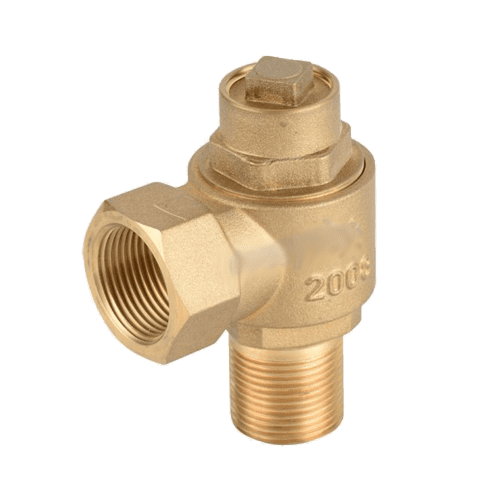

Durable Brass Ferrule Cock for Water Supply Systems

The ferrule cock is an important part of the plumbing system in industries and businesses. These valves are designed to regulate the amount of water that can pass through a service line. It is admired for its strength as well as being easy to use making it an essential feature in today’s municipal water supply systems. Another kind, brass ferrule cocks have extra resistance capacity against corrosion which makes them best suited for visible installations.

Material Specifications:

The ferrules are made out of high-quality brass so that they last long and remain dependable. We select materials based on their strengths and ability to resist wearing out; besides this, we also ensure that our products meet all environmental safety requirements hence there are environment-friendly options available too. By doing so, Brass Ferrule Cock Supplier has become synonymous with sustainable plumbing solutions provider.

Technical Specifications:

Our range comes in different sizes ranging from 1/2 inch up to 2 inches thus catering for various pipe applications while allowing flexibility during the installation process as well. The valves have been tested under pressure of 200 psi meaning they can work effectively even in low or high-pressure systems depending on the need at hand. The only thing you need to do is turn it a quarter way round which connects or disconnects supply thereby regulating flow quickly where necessary

Standards and Compliance

In terms of conformity to international standards, the Ferrule Cock has ASTM and ISO certifications among others which are essential for manufacturing quality products that are dependable too. Every item created by the Ferrule Cock Manufacturer is tested rigorously to ensure that it meets these requirements thereby giving potential buyers confidence in its safety and efficiency when used in plumbing works.

Usage Instructions

For maximum performance and service life of your Ferrule Cock, you should regularly check for signs of wear or leakage during maintenance procedures. The correct fitting should be done by an authorized professional to prevent common problems such as cross-threading or over-tightening which may occur if not handled well. In case troubleshooting is needed or any other kind of support, kindly refer to the detailed manual supplied together with your Brass Ferrule Cock Supplier products or get in touch with their knowledgeable technical team through contacts provided.

Applications

Both domestic and industrial water distribution systems heavily rely on the use of this Ferrule Cock. This can act as a strategic point where control over access into different sections within a building sharing one supply line is achieved hence making it easier to maintain and manage supplies without interrupting service delivery throughout such facilities. Moreover, being made out of brass material means that it does not only look great but also resists rust therefore perfect for installations both in open places as well as hidden areas.

Features and Benefits

Features:

Robust brass construction ensures long-term durability and resistance to corrosion.

The Ferrule Cock features a simple yet effective quarter-turn mechanism that allows for quick open/close action, reducing the time needed for maintenance or emergency shut-off.

Available from trusted Ferrule Cock Manufacturer, ensuring consistent quality and reliability.

The design of the Brass Ferrule Cock incorporates a compact form factor, making it ideal for tight spaces where traditional valves might not fit.

Benefits:

Provides a reliable solution for managing water flow that minimizes the risk of leaks and water waste.

Enhances the overall efficiency of water systems by allowing for localized control and maintenance without affecting the entire network.

The use of high-quality brass materials by Brass Ferrule Cock Supplier not only extends the life of the product but also ensures that it remains free from rust and degradation over time.

Easy to install and maintain, which translates to lower long-term costs and reduced need for frequent replacements.

Related Products

To further enhance your plumbing systems, consider these complementary products:

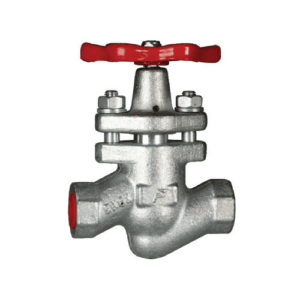

Pressure Reducing Valves: Ideal for managing water pressure within the system to prevent damage to the pipes and increase system longevity.

Ball Valves: Offer robust shut-off capabilities for larger sections of your water system, providing an excellent pairing with the Ferrule Cock for complete system control.

Check Valves: Prevent the reverse flow of water, which is crucial for systems that require one-way flow for safety and efficiency.

Secure and enhance your water supply systems with our high-quality Ferrule Cock. Our team is ready to assist you with every aspect of your purchase.

Support and Warranty Information

Our Ferrule Cocks, including Brass Ferrule Cock models, are supported by comprehensive warranties and expert customer service. Each valve is backed by a guarantee from the Ferrule Cock Supplier, covering defects in materials and workmanship. We also provide full support for installation and maintenance to ensure that your investment is protected and performs flawlessly for years to come.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.