High-Precision Stainless Steel Needle Valve for Accurate Flow Regulation

The Needle Valve is designed for precise flow control in hydraulic and pneumatic systems, making it widely used across various industries. The Control Needle Valve is particularly valuable where accurate tuning of the flow rate is required within a system. This valve can efficiently handle different pressure ranges from low to high which is why it finds its application in the oil & gas industry, chemical processing plants as well as research laboratories among others.

Material Specifications:

The SS Needle Valve is made using top-grade materials like 316 stainless steel or brass therefore ensuring good resistance against corrosion along with durability properties. By using environmentally friendly components we abide by all current ecological norms thus making this item not only efficient but sustainable also.

Technical Specifications:

Our range comprises sizes starting at 1/8” up to 1” with pressure ratings reaching 10,000 psi for each Needle Valve. Valves can be fitted with different types of ends such as NPT threads, BSPT threads, or twin ferrule tube fittings which allows them to be easily integrated into existing systems where necessary. A much stronger performer among other models is the Hydac Needle Valve thanks to its fine thread design that enables precision adjustment of flows together with a stem that doesn’t rotate hence reducing seal wear dramatically.

Requirements and Agreement

Needle valves comply with very strict safety standards and quality. Different certifications such as ISO and ASTM are followed by the Needle Valve Manufacturers. They ensure that all valves are carefully examined according to these benchmarks thus providing reliable measures for performance as well as safety. Moreover, these items meet various regulations within their fields which enable them to suit many uses.

Instructions for Use

It is advisable to undertake regular maintenance if you want your needle valve to remain functional for long. This involves cleaning the seats of valves occasionally along with stems; looking out for any leakage – and checking whether adjustments have stayed accurate or not. During installation, one should follow instructions given by a Needle Valve Supplier so that you don’t do things wrongly like cross threading among others which could lead to inefficiency during operation or even damage the whole system.

Applications

The needle valve finds wide application in precision fluid management systems throughout different sectors ranging from the pharmaceutical industry to petrochemical processing plants. Where exact dosing or regulation of flow is needed, this device becomes an ideal choice due to its capability of controlling with precision each drop of liquid passing through it at once. Particularly valuable is the control variant under dynamic conditions when precise adjustments are required repeatedly while working automatically. Additionally, the introduction of the Pin Valve provides an alternative solution for applications needing quick, needle-like control in smaller or more delicate systems.

Features and Benefits

Features:

The Needle Valve boasts high precision flow control due to its finely threaded stem.

It is made of durable materials such as Stainless Needle Valve that can resist harsh chemicals and last long.

This variant is also known as the SS Needle Valve which has even more resistance against corrosion making it suitable for use in hostile environments.

Manual and automated operations are accommodated with these features integrated into it which is called as Needle Valve Control, to meet the specific needs of different users’ systems.

Benefits:

Critical applications in medical, research, or industrial settings require reliability along with consistency in managing flows – this product delivers just that!

Compared to other types like pin valves etc., they leak less frequently because their construction makes them robust enough; hence minimizing maintenance costs too; besides using quality materials throughout including those found within Control Needle Valve.

System safety gets improved by such a move while at the same time enhancing efficiency within it thus giving operators peace of mind since both these aspects matter greatly according to engineers’ experience also expressed hereinbefore.

To operate machines easily where adjustments must be made rapidly then the design featuring quick & easy control called Pin Valve comes in handy.

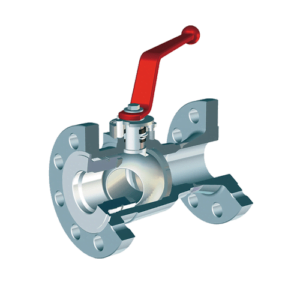

Related Products

For those who want to increase the capabilities of their system, here are some related products that may be useful:

Pressure Regulators: This is often used with SS Needle Valve which helps in stabilizing the system against fluctuations in input pressure while maintaining constant output.

Ball valves: These can be used for on/off control in larger pipelines as they provide stronger alternative controls about higher flow rates than Control Needle Valve.

Check Valves: They are designed to prevent reverse flow and ensure unidirectional flow integrity; therefore; they go hand-in-hand with Needle Valve Control in complex systems

Enhance your fluid management systems with our precise and reliable Needle Valve. “Request a Quote” for bulk orders. For more details or any questions about this product please contact us. Our highly skilled team is available round the clock so feel free to reach out at any time!

Support & Warranty Information

All types including pin valves and stainless needle valves have all necessary support plus warranty coverage which caters to both materials used as well as workmanship applied during the manufacturing process where defects might arise from. At our company we value customers therefore we ensure that everything is done right from selecting appropriate valves up to installing them correctly and then ensuring proper maintenance throughout their lifespan this will enable achieve maximum performance levels.