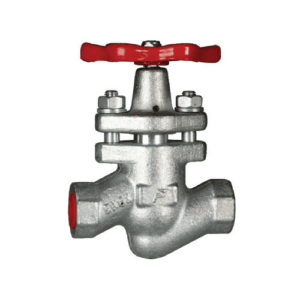

High-Efficiency Anti-Reflux Valve for Fluid Control Systems

A check valve, which is also called a reflux valve, has been made to only allow liquid flow in one direction. This is done by preventing any backflow within a pipe system. This feature becomes very useful, for example, in the management of wastewater, irrigation systems, and other industrial processes where contamination or damage could arise from backflows happening. Moreover, among its different applications, it can be observed that this device was created with medical uses in mind too because there exists an Anti Reflux Valve designed specifically against gastric reflux.

Material Specifications:

To make the Reflux Valve resistant to rusting or being worn out easily, it is made of durable materials like stainless steel and PVC. To comply with environmental regulations while at the same time increasing its lifespan, sustainable resources have been incorporated during manufacture. On the other hand, NG Anti Reflux Valves come fitted with special parts which are safe for use within medical settings due to their adherence to strict health as well as safety standards.

Technical Specifications:

Our Reflux Valve may be purchased in sizes as small as one-half inch or as large as two feet across which should fit any pipe specification you might have. They are rated for pressures of up to five hundred pounds per square inch and can be used in both low-pressure systems like gravity-fed irrigation lines and high-pressure steam applications such as those found at power plants. Additionally, these valves’ anti-reflux properties come from their being spring-loaded; this means they close very quickly after flow stops – an important feature when trying to prevent backflow or water hammer.

Standards & Compliance

The Reflux Valve complies with many international standards including but not limited to ASTM and ISO 9001 certifications which ensure that its quality is of the highest level possible. Moreover, each manufacturer also follows safety rules along with quality control procedures so that all necessary conditions are met while installing this device, preventing reliably against reverse flow thus making it widely applicable within different branches of industry.

Usage Instructions

To ensure the best performance and longest life of the reflux valve, check for debris or wear regularly, particularly in the closure mechanism and valve seat. Correct installation is important to achieve optimum functionality as recommended by the manufacturer of reflux valves. For more detailed assistance on operational best practices and troubleshooting please refer to our user manual or get in touch with our support team of professionals who can be reached via the price list link.

Applications

Reflux valves are mainly used where stopping backflow is necessary to maintain fluid process integrity and safety. In water treatment plants, these prevent dirty water from flowing back into the clean supply; also, they find application within different industries whereby equipment damage may occur due to chemicals flowing back or cause health risks posed by them. Additionally, anti-reflux valves are very important components of medical devices like ventilators and feeding tubes which are designed so that gastric contents cannot enter other parts of a patient’s body while being used.

Features and Benefits

Features:

Robust construction ensures long-term reliability and resistance to typical wear and environmental factors.

The NG Anti Reflux Valve is designed with non-toxic materials suitable for medical use, ensuring patient safety and compatibility with various medical applications.

The Valves Anti Reflux incorporate advanced design features that provide a quick response to flow changes, efficiently preventing any backflow.

Benefits:

Enhances system safety by reliably preventing the reverse flow of potentially harmful fluids.

Reduces maintenance costs associated with damage from backflow incidents.

Reflux Valve Manufacturer models are easy to install and maintain, offering versatile solutions that fit a broad range of industrial and medical applications.

The availability of Reflux Valve Price List and Reflux Valve Supplier options provides flexibility and ease of procurement for businesses of all sizes.

Related Products

To complement your reflux prevention setup, consider these related products:

Pressure Relief Valves: Ideal for systems that also require pressure control in addition to backflow prevention.

Gate Valves: Suitable for larger-scale applications where a shut-off mechanism is necessary alongside reflux prevention.

Ball Valves: Provide a robust alternative for flow control that can be integrated into systems needing precise operation alongside Reflux Valve functionalities.

Ensure your systems are secure and efficient with our high-quality Reflux Valve. Enhance your setup with the assurance of performance and quality that our Reflux Valve Supplier network offers.

Support and Warranty Information

Our Reflux Valves, including the Anti Reflux Valve and NG Anti Reflux Valve, come with extensive support and warranties that cover manufacturing defects and performance assurances. Backed by our Reflux Valve Manufacturer, you can expect responsive customer service and detailed technical support to ensure your valve operates flawlessly.