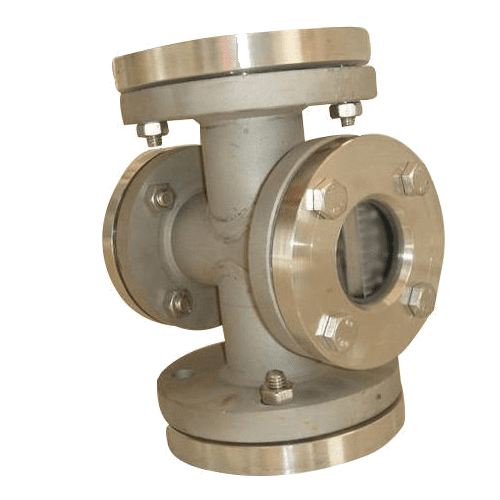

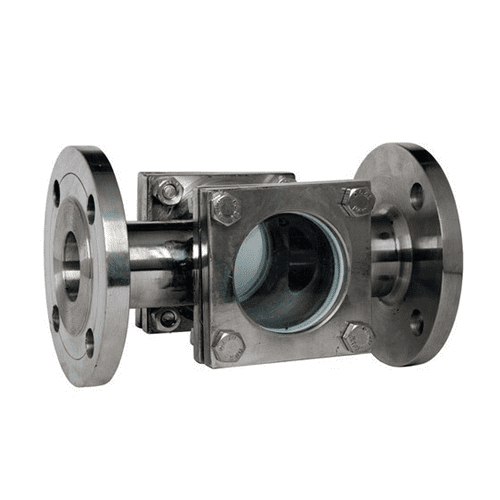

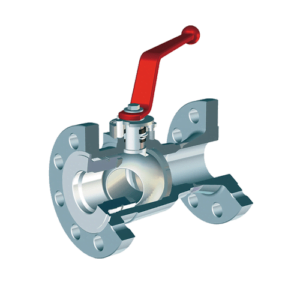

High-Clarity Sight Glass Valve for Fluid Monitoring Applications

The Sight Glass Valve is an all-important component in whatever number of industrial applications that require a clear view of fluid flow and characteristics in pipelines and tanks. This is very important, especially for monitoring and controlling processes that require fluid to be seen, in industries like chemical, pharmaceutical, and food processing. The guarantee that the [Sight Glass Valve Manufacturer] gives is the fact that these valves have maximum visibility while keeping the systems they are used in with their integrity and safety.

Material Specifications:

Our sight glass valves are made of hard materials such as borosilicate glass and stainless steel, which are resistant to high temperatures and corrosive materials. The frames and fittings are majorly done by [Glass Valves Manufacturer in India] with materials that are not only eco-friendly but are also of material strength, resulting in great performance within harsh industrial surroundings.

Technical Specifications:

- Glass type: Borosilicate, known for its high thermal resistance

- Valve sizes ranging from 1/2 inch to 12 inches

- Pressure ratings up to 150 PSI

- Temperature tolerance up to 250°C

Connection types include flanged, threaded, or welded, providing flexibility for various installation requirements

- These features are designed to meet the demanding specifications of industries that require visual monitoring of their processes.

Standards and Compliance

Our Sight Glass Valves are manufactured to the highest industry standards of product quality and safety, including ASTM and ISO. This assurance has been undertaken, since we are one of the leading manufacturers of Boiler Gauge Glass Valves, that these valves meet all the stringent quality and performance tests set up for compliance with global safety and operational requirements. This assurance allows our customers to confidently rely on the reliability of the valve in critical applications.

Usage Instructions

To maximize the performance and lifespan of your [Sight Glass Valve], follow these guidelines:

- Clean the glass from time to time to ensure that vision is not lost. Periodically, inspect and replace cloudy or cracked glass.

- Replace the seals and gaskets if they show any wear or leakage.

- Don’t use any abrasive cleaning agents, as they can scratch or weaken the glass.

- Installation and specific maintenance should be done with reference to the following instructions from the [Sight Glass Valve Manufacturer] or by consulting with our technical support team.

This content incorporates the keywords provided quite well, in detailing and engaging features, benefits, and operation guidelines of the Sight Glass Valve. Do let me know in case you need more details or other sections of the content tailor-made.

Applications

The [Sight Glass Valve] is utilized across various industries for its ability to provide a direct view into systems, ensuring proper flow and condition monitoring:

- Chemical Processing: It helps the operators to monitor the flow and reaction of chemicals within the pipes and reactors in order to maintain safety and efficiency in the procedure.

- Pharmaceutical Manufacturing: In critical processes in which contamination and process integrity are to be observed.

- Food and Beverage Production: It enables visual inspection of fluids for quality as well as health and safety standards.

- Boilers and Steam Systems: [Boiler Gauge Glass Valves] are critical to the observation of both the water level and the steam level of a boiler, thereby avoiding boiler failure resulting from conditions of overfilling or partial filling of the boiler drum water.

Features and Benefits

Features

- Real-Time Monitoring: It allows one to view in real-time the state of Flow and the state of Content without interference.

- Durability: The [Glass Valves in India manufacturer] is made of tough and strong material that can withstand the most destructive conditions.

- Safety Enhancement: Crucial in systems where pressure, temperature, and fluid integrity must be maintained so that disasters can be avoided.

Benefits:

- Operational Efficiency: Assists in process control for increased efficiency with uninterrupted real-time monitoring.

- Cost Savings: There are reduced maintenance costs and fewer system shutdowns, which lead to savings on operational costs.

- Enhanced Safety: Minimizes risks by allowing for the immediate detection of issues such as leaks, blockages, or chemical reactions.

Related Products

To ensure comprehensive system management, consider integrating these related products:

- Pressure Gauges: Provides continuous monitoring of pressure levels, combined with a visual check of safe working parameters of systems.

- Flow Meters: Measure and monitor the rate of flow through the pipes, which complements the visual data provided by the sight glass.

- Temperature Sensors: Control of the correct temperature setpoints; ensure that the processes are performed at optimal temperatures.

Support and Warranty Information

Availability of Support and Warranty Our [Sight Glass Valves], including the [Boiler Gauge Glass Valves], are [highly] covered under warranty and supported strongly in the aftermarket. We’ll get you installation information, operation assistance, and help troubleshooting right to ensure your valves are operating well to keep your system effective their entire life.