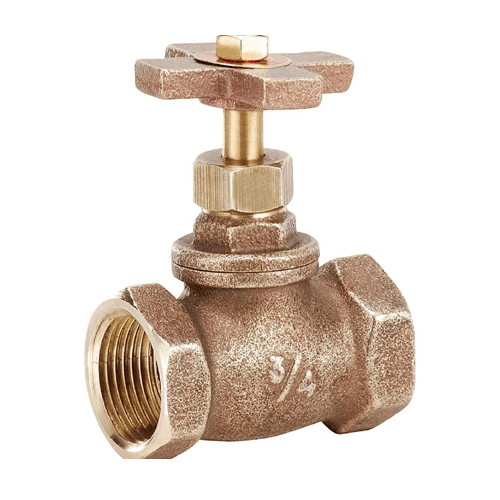

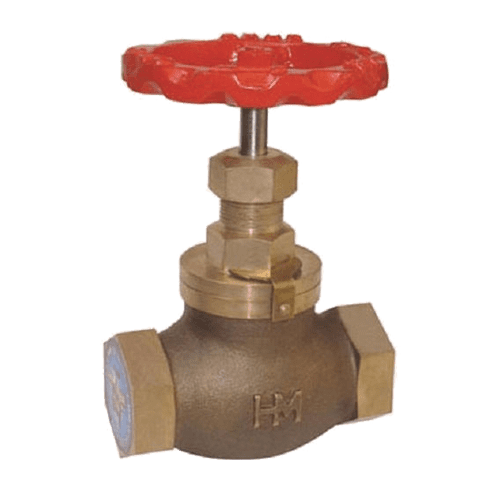

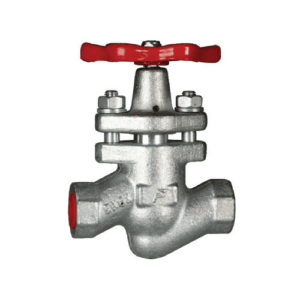

Precision-Engineered Stop Valve for Effective Flow Control

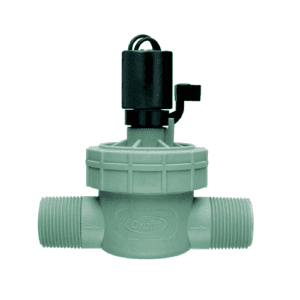

It is one of the applications of the Stop Valve that controls most of the flow of fluid in any piping system, from plumbing to industrial fluid processing. The capability of quickly stopping fluid flow makes the product very important in emergency cases or during maintenance activities. Its capability in different environments is further enhanced with the availability of two main types: the [Steam Stop Valve] and [Angle Stop Valve].

Material Specifications:

Our Stop Valves, fabricated using such corrosion-resisting materials as brass, stainless steel, and PVC, assure resistance in terms of function durability. Such chosen eco-friendly materials align with our policy of sustainable manufacture. Each of the materials is tested to ensure it possesses the highest levels of strength and longevity for challenging applications.

Technical Specifications:

- Sizes range from 1/4 inch to 12 inches

- Pressure ratings up to 500 PSI

- Temperature range suitable for medium up to 200°C

- Available configurations include [Stopcock Valve] and [Stop Cork Valve], designed for specific use cases such as laboratory settings and fine control applications.

- These specifications are designed to cater to a broad spectrum of industrial, commercial, and residential needs, ensuring versatility and reliability.

Standards and Compliance

Every stop valve in our collection is designed and manufactured to exceed the industry standards, with the acceptance of ASTM and ISO 9001. Being one of the leading stopcock manufacturers, we leave no valve unturned for quality and safety testing that affirms whether the design matches the international safety and quality standards. That’s the kind of strict compliance that builds confidence in the reliability and safety of our products in customers.

Usage Instructions

To ensure the optimal performance and longevity of your [Stop Valve], follow these guidelines:

- Check for leakage or damage of the valve periodically.

- Open the valve periodically to prevent seizing up, especially in steam control-type valves, like the [Steam Stop Valve].

- Lubricate all moving parts if the construction material used to manufacture the valve and the service conditions so require.

- Carefully follow the installation guidelines so as to get the proper functioning and alignment in your system.

- Please consult the attached manual or contact [Stop Valve Manufacturer] for troubleshooting and other support or maintenance recommendations.

Applications

The [Stop Valve] plays a crucial role in a wide range of applications due to its ability to provide reliable shut-off in fluid systems:

- Water Supply Systems: These regulate the dispensing of water in buildings, whether residential or commercial, and can stop its flow when it is not regulated for maintenance or in the case of an emergency.

- Steam Systems: The [Steam Stop Valve] is developed primarily for high-temperature and high-pressure steam.

- Chemical Processing: Used in service of [Stop Valve] to permit maintenance and for emergency shut-off to isolate portions of a system to avert chemical leaks.

- HVAC Systems: It serves to regulate and stop the flow of air and fluid in the circuits used in heating, ventilation, and air conditioning systems.

Features and Benefits

Features

- Quick Isolation: It allows for fast and easy fluid isolation without the risk of breakage in the system during maintenance.

- Versatility: Available in many types, such as the [Angle Stop Valve], for corner installations, and the [Stopcock Valve], for precision control in laboratory applications.

- Durability: Built of materials such as stainless steel and brass, which grant a long life and the capability to resist corrosion and wear.

Benefits:

- Safety Enhancement: Provides essential control for emergencies and enhances the overall safety of the system.

- Operational Efficiency: This allows easy maintenance and inspection routines of a system by enabling isolation of its sections without disturbance to the whole operation.

- Cost-Effective: It reduces the chances of downtime and repair costs through strong features of control with rapid response.

Related Products

To build a comprehensive fluid control system, consider integrating these related products:

- [Check Valves]: Prevent backflow to complement the stop valve to enhance system integrity.

- [Control Valves]: They give precision flow control to operate with the sealing properties of shutoff valves.

- [Safety Relief Valves]: Prevent overpressure with a stop valve to keep pressure within safe limits for the system.

Support and Warranty Information

Our [Stop Valves], including specialty models such as the [Steam Stop Valve] and the angle stop valve, are guaranteed and supported. We provide you with full installation and operation details together with each valve, and our troubleshooting support may be of help in checking for proper and dependable performance of our valves.