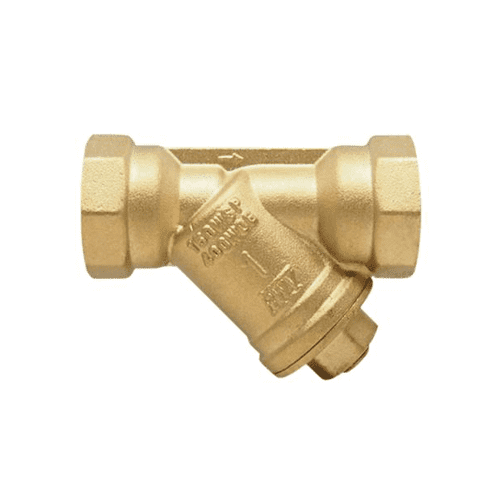

Durable Stainless Steel Y Strainer Valve for Effective Filtration

In such circumstances, the need for a Y Strainer Valve is very high to protect a piped system from any debris and maintain a debris-free piped system. A Y Strainer is very commonly used from the HVAC systems of residences up to and including industrial processing plants. The Y Strainer Valve designs by the [Stainless Steel Y Strainer Manufacturer] are made to apply to a large number of fluid types in large numbers in a wide range of environments, offering high durability and corrosion resistance.

Material Specifications:

CPVC, stainless steel, and cast iron are some of the high-quality materials used in making our Y Strainers. Lightweight but rugged, the CPVC Y Strainer from [CPVC Y Strainer Manufacturer] is a great option for chemical and other corrosive environments. Stainless steel provides excellent strength and long-lasting material for high-pressure applications.

Technical Specifications:

- Sizes available from 1/2 inch to 24 inches

- Pressure ratings up to 600 PSI

- Temperature range from -20°C to 200°C

- Features include flanged, threaded, or welded connections for versatile installation options

- These specifications make our products at [Y Strainer Filter Manufacturer] versatile for various systems, therefore making them very applicable and effective in debris removal.

Standards and Compliance

Every one of our Strainer Valves is manufactured to exacting standards, such as ASTM and ISO 9001, attesting to quality and safety. Being a responsible Y Strainer Manufacturer, we take utmost care with stringent testing protocols to ensure the reliability in the performance of every product under specified conditions. In a way, these are proofs of quality and reliability for our valves in winning the trust and satisfaction of the clients.

Usage Instructions

To ensure the longevity and efficiency of your [Y Strainer Valve], follow these maintenance guidelines:

- In this regard, one should check the strainer basket regularly and clean it against blockage, reducing the flow rate and possibly increasing pressure drop.

- Inspect the body and seals for wear and damage in case of an aggressive fluid.

- This will assure that the installation is in the direction of flow as shown on the valve body to avoid incorrect setup.

- For more detailed maintenance tips or for troubleshooting, refer to the maintenance manual from the [Strainer Valve Manufacturer] or otherwise contact our technical team.

Applications

The [Y-Strainer] can be installed in a variety of industrial and residential applications and is indispensable because of its capability to effectively filter out debris:

- Industrial Processing: This finds application in chemical and petrochemical plants, food processing, and other industries for the removal of those particles that would cause harm to the equipment and contaminate the product.

- Water Treatment: A critical application at municipal and industrial facilities alike is a means by which trash and other debris can first be removed from water before further treatment.

- HVAC Systems: Designed to prevent the particulate matter from damaging components such as pumps, meters, and control valves.

- Irrigation Systems: Prevents clogging of sprinkler heads and drip irrigation components by filtering out sediments and debris.

Features and Benefits

Features

- High Filtration Efficiency: Manufacturers of Y strainer filters design strainers so that the debris in the fluid is easily removed to give a clear, uninterrupted flow.

- Robust Construction: Y strainers from [Stainless Steel Y Strainer Manufacturer] are designed so that they are robust and withstand any sort of abuse, yet effectively provide performance in any severe environmental condition.

- Easy Maintenance: It is possible to remove and replace the strainer basket without taking the system off-line.

Benefits:

- Extended Equipment Lifespan: Y strainers prevent debris from passing into the crucial parts of the system, thus lowering the rate of wear and tear on these elements, and eventually extending the life of the equipment.

- Operational Efficiency: The guarantee of uninterrupted pressure that will also increase the system’s efficiency and reduce energy costs.

- Versatility: Available in all manner of materials, including those for [CPVC Y Strainer Manufacturer], to handle varied media and environmental conditions.

Related Products

Use the following products as possible complimentary integrations to give a full system solution:

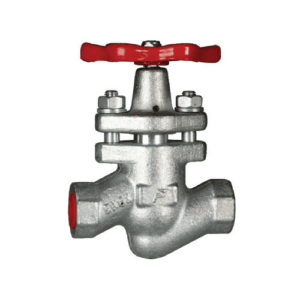

- [Check Valves]: Provides for unidirectional fluid flow, thereby ensuring better safety against any problem or issue related to the backflow of fluid.

- [Pressure Relief Valves]: Protect the systems from overpressure situations that could be fairly consequential in systems where debris might have built up, causing pressure surges.

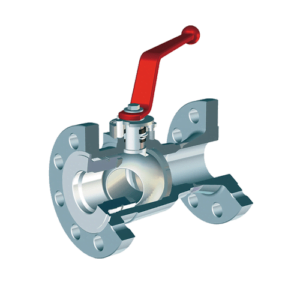

- [Ball Valves]: Provides an easy means of shutting off flow for maintenance or in case of emergency, and it works in conjunction with the Y Strainers to control your system.

Support and Warranty Information

Our Y Strainers, whether from a [CPVC Y Strainer Manufacturer] or a [Stainless Steel Y Strainer Manufacturer], come with complete warranties for our customers and after-sale customer care support. Our customers further receive installation, operation, and maintenance assistance to ensure that your systems operate smoothly.