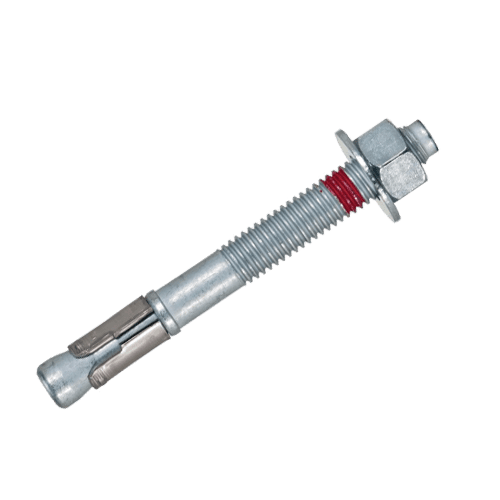

Wedge Anchor

The [Wedge Anchor] is a high-performance mechanical fastener used to secure structural and non-structural elements to concrete. It provides a strong, reliable hold, ensuring the stability and integrity of installations in various construction applications. These anchors are essential in securing frameworks, machinery, and safety barriers.

Material Specifications

We manufacture our wedge anchor products from premium-grade materials, such as stainless steel, carbon steel, and galvanized steel. This ensures distinct strength, good corrosion resistance, and high durability. The Anchor Bolt and Anchor Fastener are particularly noted for their performance and reliability in the harshest environments, providing heavy-duty anchoring solutions.

Technical Specifications

These are various lengths to meet the application needs, being from 1/4 inch to 1 inch in diameter and up to 12-inch length. They can carry a tensile load up to 4,000 lbs and a shear load up to 3,500 lbs. The Wedge Type Anchor Bolt, the Expansion Anchor Bolt, and the Mechanical Anchor Fastener are products with the most recent design improvements, offering greater competence in diverse operating conditions. Specific specifications are the diameter of the anchor, the length, and the pull-out strength.

Standards and Compliance

Every [Wedge Anchor] follows international standards like ASTM, ACI, and ISO 9001. As reliable [Wedge Anchor Manufacturers], we ensure that all our products are put through the prescribed testing laid down under such standards and commit to our customers about the safety, reliability, and performance. Certification from [Wedge Anchor Suppliers] testifies to quality management and excellence in customer service.

Usage Instructions

Failure to follow these directions may reduce the performance of your [Wedge Anchor], limit its lifetime, and compromise safety. Drill a hole to the required size. Remove the material from the hole and insert the anchor. Expand the fixture by tightening the anchor bolt. Confirm the installation using the user guide or by contacting our technical support group.

Applications

The Wedge Anchor is perhaps one of the most important parts in every construction and industrial project where there is a necessity for holding up something serious and long-lasting. It is used to ensure that structural beams are anchored, to hold heavy machinery in its place, and attach safety barriers to the ground. Such kind of fastener bears a critically important meaning in high-loading applications where reliability is very much important.

The [Wedge Anchor] application may be in-plant or outdoor for where it materially provides substantial resistance to severe weather conditions and chemicals. This strong composition ensures both reliability and durability under various conditions. The [Expansion Anchor Bolt] is very popular due to its versatility in anchoring fixtures into concrete and masonry structures.

The [Wedge Anchor] is a high-stress bolt designed to provide superior fastening capabilities in the most-stressed working environments. The solid mechanism ensures high durability and reliability, hence making it ideal for the most stringent and tough conditions. Manufacturers of wedge anchors make a wide range of wedge anchors, including some customized forms for distinct industrial needs. This is what makes it the most favored supplier for projects requiring precision engineering with high levels of reliability in their products.

Features and Benefits

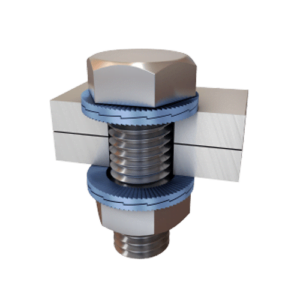

Features:

- The best holding power is provided by humans with advanced expansion technology.

- High-strength [Wedge Type Anchor Bolt] can carry large loads and is applied in critical applications related to structures.

- The product is designed to be as versatile as possible; that way, it significantly helps reduce the time of installation and the cost of labor.

Benefits:

- Built to be of long-life service and with low maintenance, since they are done using durable building materials and designed building.

- This helps in structural security and safety with the capability of the [Wedge Anchor] to hold strong.

- [Wedge Anchor Suppliers] competitively priced All competitive prices of anchor bolts amount to cost effectiveness for the businesses without the need to compromise with quality solutions for anchoring at economical rates.

Related Products

The following integrative related products help ensure overall comprehensive protection and efficiency:

- [Chemical Anchors]: Offers strong anchoring solutions for all types of construction needs.

- [Anchor Fasteners]: Provides precise and extremely sturdy anchoring solutions besides the retention capacity for wedge anchors.

- [Mechanical Fasteners]: Structures in concrete and masonry construction guarantee long operational life with a dependable fastening system that maintains structure stability.

Call to Action

“Request a Quote” for bulk prices, or “Contact Us for More Info” for tailored solutions. Our expert team from [Wedge Anchor Manufacturers] is waiting for the chance to help you choose the perfect anchor for your unique needs.

Support and Warranty Information

Our wedge anchors, from a wedge-type anchor bolt to an expansion anchor bolt, are supplied with a full support warranty and complete customer support service from reputable wedge anchor suppliers. To make sure that your anchor will operate in top performance through its service life, we offer installation, operational, and troubleshooting services.

- The installation of anchors won’t be possible. This will result in no holding values

- It would get difficult to remove the anchor once drilled inside, which would ultimately destroy the material.

- Other base materials would get damaged while the installation process

- If the material is hollow and absorptive the wedge anchor will spin the whole.

- Working/ functioning of wedge anchor

- 304 stainless steel

- 316 stainless steel

| Name of the material | Advantages | Disadvantages | Applications |

| Stainless steel | They could be used in an atmosphere with extreme conditions.They are highly durable. | They are expensive. | They are used in the fencepostThey are used in fixtures that are to be installed in seaways.Light posts |

| Galvanized | They are useful in indoor as well as outdoor locations.They could also be treated with other base materials such as lumber | They could not be used in extreme atmospheric conditions | Indoor fixturesStaircases |

| Zinc | Very cost-effectiveEasy to installLightweight | They are not reliable for heavy fixturesThey could be easily corroded | Electric pipesSignboards |

- Wide variety of choices